Growers are in the dark as to how best to control their LED lighting. There is currently no consensus on the optimal spectrum for plant growth of any species, creating significant confusion for growers as to how best their LED lights. It is known that different wavelengths of light affect different aspects of plant growth but reliably attributing these factors has so far proved challenging. In addition, the growing climate strongly affects the plant's ability to use light efficiently, further complicating the process of LED optimization.

While lighting recipes developed in research environments can provide valuable insights into the effects of different light spectra on plant growth, they do not translate directly to production environments. For example, certain crops will be more or less responsive to specific light spectra, depending on factors such as their growth stage and the environmental conditions in which they are being grown. As a result, it is difficult to provide standardized recipes to growers who must instead experiment with different approaches to find the optimal solution for their specific needs.

Credits: Agrolux

Chlorophyll fluorescence determines plant light efficiency in production

Chlorophyll fluorescence is a fascinating phenomenon that offers a window into the inner workings of plants, particularly how they use light. When plants absorb sunlight, they use most of it to power photosynthesis. However, not all the absorbed light is used and some of it is re-emitted, known as fluorescence. This emission is not visible to the naked eye but can be detected using specialized instruments.

The amount of fluorescence provides insights into the efficiency with which plants convert light energy into chemical energy during photosynthesis. In this way, the technique can be used to optimize the lighting in growing environments.

Finding the optimal RGB-FR spectrum

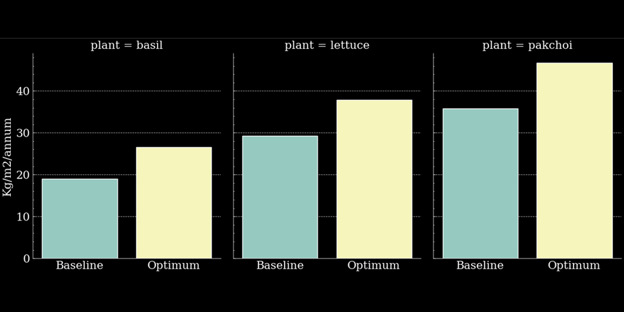

Gardin's sensor offers a scalable and affordable method to monitor the light-use efficiency of plants in production environments. The hypothesis was that every growing facility is different and that by tailoring a light recipe based on measurements from the plant, we could achieve significantly higher yields. To put this to the test, our research team attempted to optimize the ratio of red, green, blue, and far-red lights for three species using machine learning and chlorophyll fluorescence.

The project started with baseline recipes that already delivered high yields but we thought could be improved by tailoring the light spectrum for specific stages in the plant growth cycle. Each growth cycle was split into three stages with separate light recipes. With the addition of growth cycle duration and photoperiod as additional parameters, this created a 14 variable optimization challenge. Each crop also had specific constraints on product height and quality, to comply with retailer standards.

It was important to test multiple variables at the same time, due to the known interactions between light spectra that give rise to phenomena such as the Emerson Effect. This meant a traditional experimental design could not be used not only because of the sheer length of time such an experiment would require but also because it would miss fundamental biological processes.

A novel approach to spectrum optimization

To tackle this challenge, Gardin used its innovative chlorophyll fluorescence sensor to monitor photosynthetic activity in the plants and combined this with machine learning techniques to find the optimal light recipe for the specific environment. Three species were grown in parallel - basil, lettuce and pak choi - in batches of five different lighting combinations per optimization step. Each crop required around five batches, giving a total of total of twenty-five experiments per species, to find the optimal recipe. This is an extremely time efficient method for a multi-factor experiment with so many variables and could be generalized to any crop. For example, the same approach could be applied to tomatoes, using crop registration parameters taken each week for optimizing growth rate.

The improvements were as dramatic as we expected, with annualized yields increasing by at least 30% on every species. These results demonstrate the significant improvements that can be made by tailoring light spectra to the local environment and finding the correct balance of RGB-FR for distinct stages in plant development.

Statistics by Gardin

Optimizing dimmable lighting control

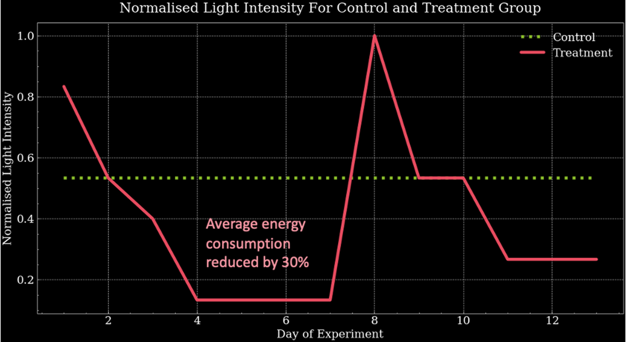

Once inroads into optimal spectra have been made, further improvements can be made by dynamically controlling the light intensity based on the efficiency of photosynthesis at different light levels. The efficiency of light conversion in plants is constantly changing due to changes in climate, time of day and development stage. In addition, every batch of plants will be different due to the slightly different environment in which they were grown. This means that optimized supplemental lighting should also take into consideration the plants being grown at that particular moment.

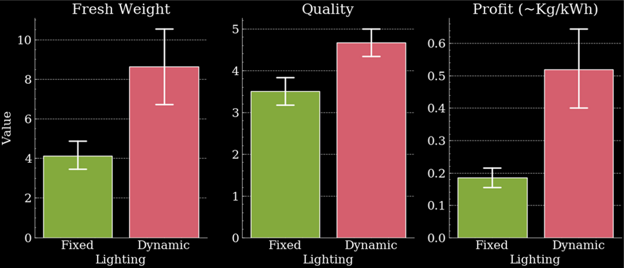

Using its innovative sensor, Gardin can determine the optimal PPFD for growth in less than ten minutes. The optimal PPFD is decided as the light level at which the plant is neither limited by the availability of light nor the availability of CO2 and the photosynthesis is in balance. To demonstrate this approach, our research team set up an experiment comparing a fixed light recipe (200umol) to a dynamic recipe on rocket (arugula) plants over a two week period. At the start of each day, Gardin determined the optimal intensity for the treatment group which varied from being above and below the intensity for the control.

Over the course of two weeks, the treatment group reduced energy consumption by 30%, increased fresh weight by 100% and had improvements to an agronomist score of plant quality. This experiment successfully demonstrated the remarkable improvements that can be made by dynamically controlling the intensity of light to how much light can be usefully consumed by the plant.

It was insightful that this experiment demonstrate extra light does not provide the plant with extra energy, instead it may cause photo damage in the plant which must expend energy dissipating the extra light. Whilst this approach was demonstrated with LED lighting, it is equally applicable to the use of shading screens during the summer.

For more information:

Gardin

Damiana Price, Head of Marketing

d.price@gardin.co.uk

www.gardin.ag