Who grows eggplants better—AI or an experienced grower? The team at DC Farms dared to take on the challenge and partnered with Koidra to explore data-driven growing. The innovative greenhouse company conducted a trial comparing AI-driven and grower-controlled climate management for eggplant cultivation in Ontario, Canada. The trial assessed the impact of automated climate control on yield and efficiency. By leveraging Koidra's solutions, DC Farms achieved measurable improvements in productivity and operational efficiency.

Trialing the system

DC Farms, a family-owned and operated business since 1972, has grown from a modest 22-acre fruit and vegetable farm into a highly specialized greenhouse operation. Located in Ontario, Canada, DC Farms is known for cultivating high-quality produce with a strong commitment to sustainability and advanced technology.

DC Farms is continuously upscaling and is currently taking its sixth commercial phase in production. Using modern technologies is essential for being able to expand, which is why DC Farms last year tested KoPilot. This AI-driven climate control system is developed by Koidra to deliver operational stability in the greenhouse, and reduce manual tasks and errors. The use of KoPilot was combined with the Koidra analytics platfom DataPilot, developed to help growers with actionable insights for prompt intervention.

Click to enlarge

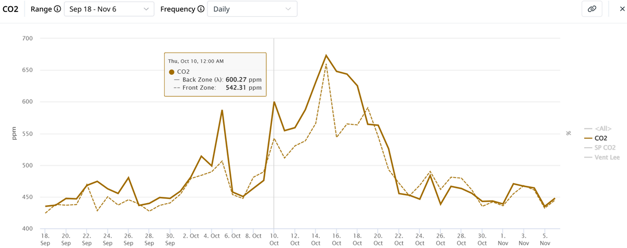

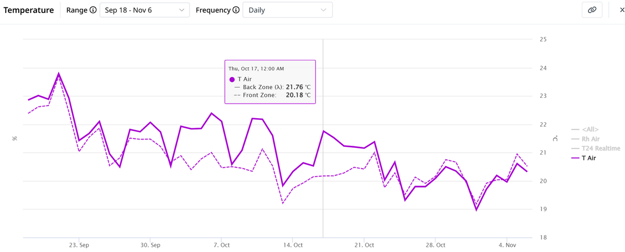

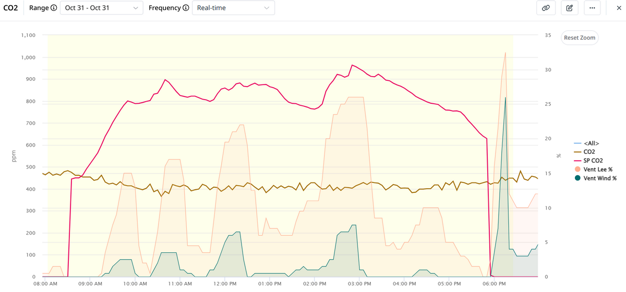

The team with DC Farms ran a trial with these systems and compared the results to a zone manually managed. The trial ran from September 18 to November 6, 2024. Results from the two-month period showed a 5% increase in yield (kg/m²) in the AI-managed zone. Precise temperature management played a crucial role in the yield and efficiency gains. "Regarding ventilation, we dynamically adjusted to balance fresh air circulation and CO₂ retention. This also improved CO₂ management: we maintained an average concentration of 595 ppm in the KoPilot zone, significantly higher than the 480 ppm in the grower-managed zone, leading to faster fruit development", shares Mike DelCiancio, farm manager.

"We had great results with Koidra during our first year of use. A 5% increase in production during the trial period is a promising start," he continues. "The system challenged our traditional approaches, leading to improved outcomes. I'm excited to incorporate more sensors and data in the coming season to push boundaries even further." The teams both agree this collaboration highlights the benefits of AI in modern horticulture, paving the way for DC Farms to expand automation for even greater efficiency and yield.

Overcoming hurdles

Numbers are valuable, but there's more to the transition to AI-driven growing. While Mike is known for being open to new technologies—and has tested autonomous growing solutions in the past—he encountered challenges in transitioning to data-driven growing. The shift required adopting new ways of interpreting and acting on greenhouse information, which is why he worked closely with Koidra throughout the process. "Understanding the intricate relationships between climate factors—such as temperature, humidity, and CO₂ levels—and crop performance was challenging in the past due to fragmented data presentation," he explains. Additionally, there were several operational inefficiencies. "Manual management required growers to spend excessive time on routine climate adjustments, reducing their ability to focus on strategic tasks."

Through their partnership, Koidra provided DC Farms with tools and insights to remove barriers to data-driven growing via their DataPilot and KoPilot solutions. "KoPilot autonomously manages heating, ventilation, and CO₂ levels based on crop cycles and dynamic greenhouse conditions, allowing growers to focus on critical tasks like crop strategy and problem-solving. Meanwhile, DataPilot offers a data analytics platform where growers can observe trends in real time and take action as needed", Ketut Putra, Customer Success Engineer with Koidra, and partner in the DC Farms trial, explains.

He adds that growers at DC Farms gained a deeper understanding of the relationships between climate parameters and crop performance through DataPilot's simplified dashboard and advanced analytics, reducing manual analysis and improving greenhouse management. "For example, dew point temperature (T Dew) is crucial for detecting condensation risks and managing fungal threats. T Dew can be calculated from inside and outside temperatures using a simple function. Growers can observe when the greenhouse temperature reaches the dew point and adjust KoPilot settings to reduce humidity. At the same time, KoPilot learns from grower feedback and adapts its strategies to various greenhouse conditions."

Results and future outlook

"Unlike traditional management, KoPilot maintained consistent climate conditions with minimal human intervention," Ketut summarizes. "Automation reduced errors, stabilized environmental factors, and allowed growers—including Mike—to focus on strategic initiatives rather than routine tasks. For farms facing labor constraints or looking to scale, this automation is a game-changer."

Mike adds that Koidra's system worked well, increasing production—a promising outcome. "Although KoPilot sometimes took a different approach than what I was used to, it delivered great results. It made me think and question my methods, which is ultimately a good thing." Looking ahead, future plans include expanding sensor integration, adopting predictive forecasting tools, and scaling operations to achieve even greater efficiency and yield.

For more information:

For more information:

Koidra

hello@koidra.ai

www.koidra.ai