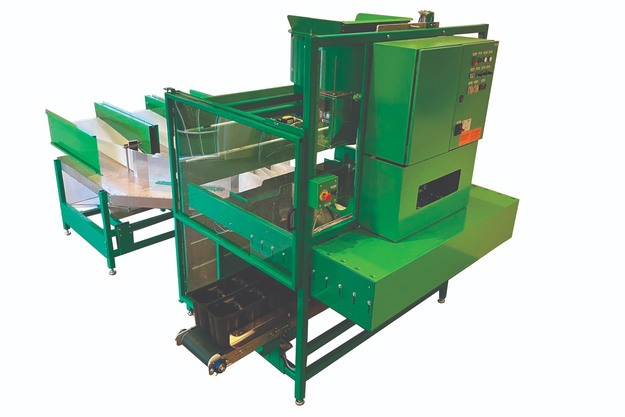

Following the launch of their Paper Pot machine, the team with Air Tray Technologies by Blackmore is now launching the 2.0 version of the machine. This patent pending production line is customized to optimize plant health and automation. "With a capacity of up to 1200 pots or 250 trays an hour, filling three at a time", shows Lars Jensen, inventor of the machine. "The paper pot 2.0 enables the grower to choose any mix. You no longer need to compromise with the media you want to use to meet the specification of the machine."

Plant health

Lars explains the Paper Pot 2.0 Machine is designed to promote healthy root development by ensuring consistent air circulation and water drainage in the root zone throughout the production cycle. "Plants develop fibrous roots when grown in the Paper Pot 2.0 Machine system, the optimal root morphology for nutrient uptake, resulting in faster growth and healthier plants more resilient to disease pressure."

Automation and integrated solutions

The Patented Paper Pot 2.0 Machine reduces inputs, labor and shipping cost. "Cost savings can be realized from planting to retail." The production line can also utilize the Air Tray rack system, offering centralized production and allowing one person to move multiple containers at one time. "This keeps employees in one location eliminating employee downtime walking from one work location to another."

According to Lars, the Paper Pot 2.0 Machine can be used in all sectors by growers needing a healthy root system but at a lower overall cost compared to traditional growing. "Air Tray Technologies by Blackmore is bringing low cost and simple automation delivering healthy & better yielding plants."

The Paper Pot 2.0 Mahcine is on display at IPM Essen in Germany in Galleria stand GA02, where also the other patented Air Tray Technologies for the Ellepot are shown, as well as the latest Plant-It-Friendly sleeve which reduces plastic at retail by up to 95%.

For more information:

Blackmore Company

info@blackmoreco.com

www.blackmoreco.com

www.air-trays.com