Curaçao enjoys year-round sunshine and consistently moderate temperatures, which might seem ideal for cultivating fruits and vegetables. However, appearances can be deceiving. Take tomatoes, for example a tomato plant requires cool nighttime temperatures at certain stages of growth, but in Curaçao, nighttime lows rarely fall below 24°C. As a result, much of the horticultural sector relies on systems that allow for partial temperature control.

Ferdinand Bouwman, who had managed a rehabilitation center on the island for years and was seeking a career change about five years ago, also opted for a controlled growing system. After experimenting with a small-scale, self-designed aquaponics setup and spending countless evenings researching vegetable cultivation online, he became intrigued by a highly controlled approach: Freight Farms. This vertical farming system, developed by a Boston-based technology company, involves growing crops in a container.

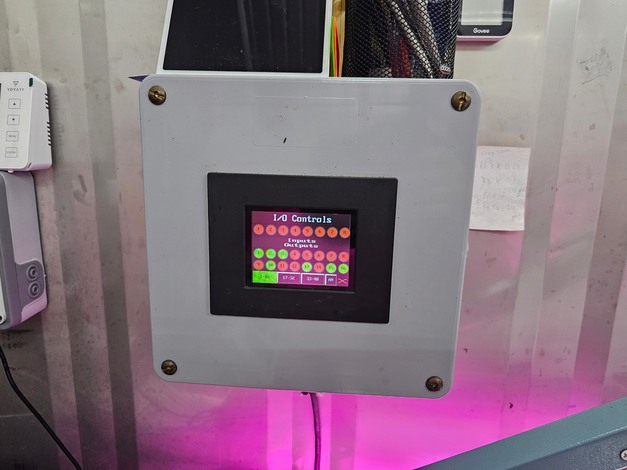

"Control over cultivation parameters is essential in Curaçao," Ferdinand explains. "The risks are too great—too much sun, fungi, bacteria, and more. I contacted Freight Farms and completed their training program. The investment was substantial, but we managed to handle it internally. Shipping the container to Curaçao during the COVID-19 pandemic was challenging. One of the great things about Freight Farms is the community; you can discuss problems with others, and their service desk is very responsive."

Solar panels and a generator

Ferdinand's vertical farm, HYBiZZ, grows thyme, rosemary, chard, arugula, edible flowers, and lettuce. The system consumes an average of 130 kWh daily. "One downside of vertical farming is the high electricity costs. To reduce these costs—since electricity prices in Curaçao are extremely high—we installed 70 solar panels and 12 batteries. This setup makes us self-sufficient between February and September when the sun is consistent. From October onward, clouds became more frequent, so we also installed a generator. In emergencies, we can still draw power from the grid. Interestingly, most electricity consumption is not for cooling but for lighting."

Quality as a key differentiator

Despite the high initial investment, Ferdinand believes his cultivation system is profitable. "Almost all food in Curaçao is imported. For lettuce alone, that's 700 tons annually. Imported produce is expensive, especially the crops I grow, as they often need to be airfreighted from the Netherlands or the United States due to their short shelf life. Our produce is delivered on the same day it's harvested, with no use of plant protection products. Customers receive fresh produce that doesn't even need to be washed. I supply restaurants and hotels daily, and demand exceeds what the container can produce. The product's fresh, crisp appearance and high moisture content are big selling points."

Inside the container, the temperature remains constant at around 20°C, with 80% humidity and a CO₂ concentration of approximately 800 ppm. "I source seeds from the Netherlands and the United States. After germinating for two to three days, the plants spend about two weeks in propagation and just under six weeks maturing. I use water from Aqualectra, which is generally of decent quality, but since it passes through an old pipe system, I filter it. Reverse osmosis would be ideal for complete control over water quality and precise nutrient addition."

Expansion plans

The container farm has become a stepping stone for Ferdinand, who is planning to scale up. "To serve more customers, I need larger yields. I'm investing in a 500 m² plastic canopy to grow lettuce varieties. Another container would be too costly. The greenhouse will reintroduce some uncontrollable factors, but with good ventilation, I hope to maintain a comfortable environment for employees. Cooling the water for the floating lettuce will be essential."

Collaboration with cultivators

Ferdinand is already in talks with Cultivators, a Breda-based company, for the new greenhouse. "The facility will produce 285,000 heads of lettuce annually—slightly larger than what we can grow in the container. Sales won't be an issue. There's interest from retailers, importers, cruise ships, and healthcare institutions. We're finalizing the business case and assessing the financial aspects. While subsidy programs exist for the islands, we're mainly seeking investors to support this promising project," he explains.

Ferdinand hopes his efforts will contribute to the growth of horticulture in Curaçao. "Horticulture is a neglected area in local policy. Agriculture doesn't even have its own ministry. Establishing one would be a vital first step for creating a long-term vision," he concludes.

For more information:

Ferdinand Bouwman

HYBiZZ B.V.

Martha Koosje 17 (Curaçao)

[email protected]

www.hybizz.store