In the context of contemporary agriculture, which has largely embraced modern farming techniques, there are certain challenges that receive less attention. These include issues like cross-contamination in hydroponic systems resulting in significant crop losses, the need for frequent replacement of parts due to wear and tear, and the focus of our discussion: clogged nozzles in aeroponic systems.

The nozzle problem

According to Wikipedia, Spray nozzles may become clogged which can impact the liquid's flow rate, impair the performance of the nozzle, or alter the spray pattern. Clogs may come from solid materials in the liquid or erosion as metal flakes from pipes get trapped in the nozzle's orifice.

How they get clogged

In Aeroponics, to grow, roots are sprayed with water and nutrients while they hang in the air. However, these nutrients contain a high number of minerals and other components that can block them from spraying and nourishing the plant, causing a loss in the crops.

Nozzles in an Aeroponic systems

In general, Aeroponics systems have fixed nozzles that spray the roots, usually several nozzles per sqm. This means that if you have a 10,000 sqm greenhouse, you have potentially tens of thousands of nozzles. Not only does this put a strain on the CAPEX, but it's also a cause of additional maintenance. So, a grower would pay someone to go check and maintain the nozzles regularly. Operationally speaking, this causes a lot of problems. On top of that, it's very difficult to evenly irrigate plants with a fixed system at scale, especially since the quality of the droplets is very pressure sensitive and would require a complex piping layout.

Since CleanGreen's spraying robot moves, the company's nozzles are not fixed. With its patented irrigation system, it guarantees that the irrigation droplets remain of high quality, regardless of where these are delivered to the roots. The mobility of CleanGreen's robot saves growers from this burden. This is because it sprays at regular intervals. There's a lower number of nozzles, positively impacting maintenance costs. The robot wouldn't solve the issue with labor, but it would surely save a grower from requiring more of it.

In short: the irrigation robot travels under the roots allowing us to save a lot of nozzles compared to a fixed system, and also to reduce maintenance needs.

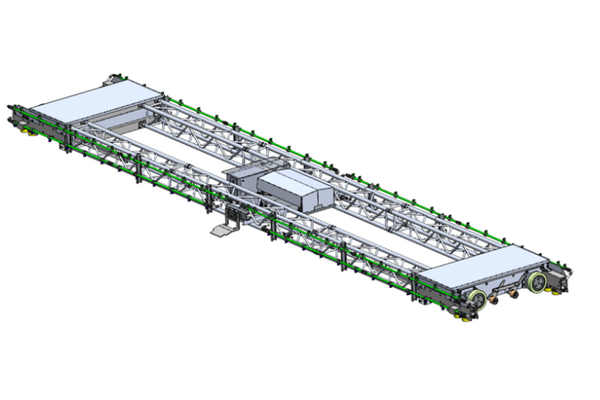

The CleanGreens system from above

The CleanGreens system from above

The CleanGreens system from below

The CleanGreens system from below

The system was inspired by conventional agriculture systems, that work for a long time in harsh conditions and can be maintained by non-technical operators.

CleanGreens had to move water hoses that contained a lot of water and were quite heavy, so the company had to adjust for the forces and friction between wheels and their tracks. CleanGreens looked for the perfect polymers that would resist the irrigation solution in the long term and have the best friction factor. Several trials and measurements over months were necessary.

The Generation 4 (GEN 4) robot.

The Generation 4 (GEN 4) robot.

For more information:

CleanGreens Solutions

cleangreens-aeroponics.com