"If you get too much of an investment, you won't be able to earn back such an amount of money," whilst hinting at former bankruptcies of vertical farm unicorns. "You have to be very careful of which systems you use, and look at the cost of production, as it will affect your baseline: whether the consumer will buy your produce, or whether they will buy it from a low-tech farm," says Edwin Ong, Director of ArianeTech, a supplier of vertical farms based in Malaysia.

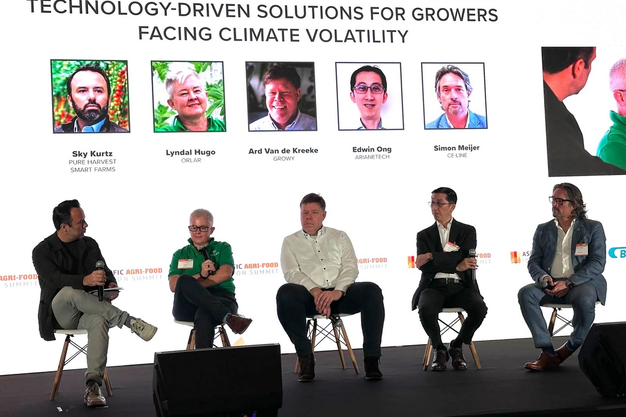

Kicking off today in Singapore, is the Asia Pacific Agri-Food Innovation Summit. An ongoing panel discussion about 'Protected cropping and indoor agtech' was led by Sky Kurtz, Founder & CEO at Pure Harvest. Sky was joined by Lyndal Hugo, Co-Founder of Orlar, Ard van de Kreeke, Founder & CEO at Growy, Edwin Ong, Director of Arianetech Pte Ltd, and Simon Meijer, CEO at CE-Line.

Sky asked the panelists if they are seeing the growth and support they'd expect with this kind of backdrop. As Lyndal shared, "It all comes down to what the consumer is willing to pay." Agreeing to that, Ard jumps in, "The bottom line is to develop a sustainable food system that also delivers affordable food for all. The only way to go is, coming up with affordable and sustainable solutions, not just high-tech and high capex solutions." Most importantly, suppliers should move away from 'over-designing' their system, as Edwin finds.

Rushing into tech, and adopting overpriced solutions

In short, Sky explained that there is a gap between what governments and consumers have been able to support in the industry, which led to the bankruptcies. So, "Why is this happening and why are companies struggling?" "Most people want to go too fast," Simon acknowledges. "Whilst, this industry is going too slow. You have to learn more about what you're growing, not adopt AI and all sorts of elements too quickly. Gather data first, and it's better to get a step-by-step approach. You cannot rush into these decisions at once."

"It's a completely new sector, in technology, and it's a familiar movement that the first entrants are failing." He explains that this is not a bad case, as it allows others to learn from it. Lessons have been learned on not paying 5-6000 euros per m2 for a vertical farm of less than 1ha and with 50 people working on it. "Someone had to step in and try out the concept, breaking up the market. Thankfully, because of that, consumers now want local, sustainable, and healthy produce so they opened up the market for us. The next-gen farmers are there to pick it up and improve."

(F.l.t.r.) Sky Kurtz, Founder & CEO at Pure Harvest. Sky was joined by Lyndal Hugo, Co-Founder of Orlar, Ard van de Kreeke, Founder & CEO at Growy, Edwin Ong, Director of Arianetech Pte Ltd, and Simon Meijer, CEO at CE-Line

(F.l.t.r.) Sky Kurtz, Founder & CEO at Pure Harvest. Sky was joined by Lyndal Hugo, Co-Founder of Orlar, Ard van de Kreeke, Founder & CEO at Growy, Edwin Ong, Director of Arianetech Pte Ltd, and Simon Meijer, CEO at CE-Line

The future of CEA

When asked about the future of CEA, Sky wonders which solutions will scale and what will be moving into laboratories. "There's enough science around to put together effective indoor farms. Yet, the only way forward is moving into private partnerships to obtain integrated farming solutions and share know-how by collaborating."

Yet, as there seems to be a big focus on hardware, Ard explains that there is a lot to win on 'genetics and nutrients' as the hardware- and software elements will 100% further improve. "The biggest issue we have is climate, water, and biodiversity. However, the developments will continue to go faster, we're in the second phase of improving the system holistically and more affordable."

Energy is a huge issue, and it will continue to be. Having a total addressable market of one billion people, we produce lettuce for less than 1 dollar per kg, as Lyndal points out. According to her, energy is such a critical issue, and there isn't much knowledge on real energy intensity. "How is green energy going to be profitable with a scalable margin that is capable of justifying the five billion dollars that was invested? The market is very small if you're using a huge amount of energy. Profitability should be at the top of your list, then margins, and then energy," says Lyndal.

'Turning energy into calories'

Often, Pure Harvest positions itself as an energy company, as they are converting sun into calories or plant material as cheaply as possible. "We do so in different ways and solutions. Yet, that realization can make you quite conscious of that embedded energy and the capital, carbon, and everything going into it," Sky concludes.

Instead of approaching a business case with, "How am I going to put the most gadgets together to create something I can attract an investment banker with?" Rather, How do I produce the highest quality product, at the lowest quality price for a billion people?" explains Lyndal. "Our technology is completely different as we make our plants stress-resilient. Through that, we're able to grow in a Mekong Delta climate of around 40 degrees, using 1% of the energy of any competition at $20 per m2 in a greenhouse. The plant becomes completely resistant through abiotic stress. With our greenhouse door never shut, it took us eight years, but now it speaks for itself."

Can we expect more hurdles?

Once vertical farming was discovered, Sky thinks it has led to overinvestment and irrational moves. "That doesn't mean the entire industry is ravaged, but currently, is experiencing a lot of difficulties. Is there more to come?" There is more to come, Ard affirms. "The market is not ready for the shake-up, and this development is not going to take place within five to ten years. A lot of new developments will come on, though."

For more information:

Asia-Pacific Agri-Food Innovation Summit

www.agrifoodinnovation.com