Despite substantial international growth - Ultramins now supplies USAF™ cavitating ultrasonic transmitters in more than 50 countries - there is still 'a lot to gain'. So says director/owner Robert de Hoo. Whether he has also been to all those 50 countries? "Fortunately not, that would be a lot in less than four years," he laughs, although he will be in Canada again in early October.

The first international order also came from Canada, from Ontario. In his move into horticulture, international business has always been an ambition. "I went looking for the world's biggest horticultural areas myself, talked to growers, and went to trade fairs. We also made ourselves known in the trade media. By now, through every grower we supply, we come back into contact with a new grower. The fact that in less than four years we have supplied more than 50 countries is absolutely fantastic. Even if we only have one or two customers in some countries. In addition, for about 1 year, we have had a partnership with Houweling HortiCulture and Houweling Americas, which gives us more clout, mainly because of their local presence."

Robert and Glenn of Ultramins in white business attire at the Canadian Greenhouse Conference 2022

Innovation

So internationally, Ultramins is doing good business. More and more growers in the Netherlands are also catching on. Yet Robert notices that the adaptation of the technology, which is new for growers, is not going as fast as he had initially thought. "The Netherlands still remains one of the most difficult markets for us. It is the market that is internationally praised for innovation and it is. But still, I notice that for our technology, adaptation is much faster in Canada and the United States, although all the major greenhouse vegetable cooperatives in the Netherlands and Belgium now have several growers who have deployed our solutions with great satisfaction."

With the USAF cavitating ultrasonic transmitters, growers around the world, from Kuwait to Kazakhstan and from Australia to Mexico, keep their water clean. "Growers see that it really works superiorly. Without major efforts, they keep their water free of bacteria, fungi, and viruses."

Early adopters

The first Dutch growers came to Ultramins looking for a way to keep ToBRFV out of their pouring water. "For this, we conducted a successful test at Ron Peters' test garden at the time. Since then, many tomato growers have been using our transmitters to their full satisfaction. In addition, there are cucumber growers who say out loud that installing the transmitters has minimized or even eliminated their virus issues."

Fusarium, a persistent problem

Internationally, Robert sees that Fusarium, among others, is also a problem that growers struggle with. "Fusarium is also within the microorganisms that are killed off with cavitation, as are most pathogens, which means we can also help these growers. That gives us a lot of satisfaction. Because if you hang up strings on 10 hectares and after 2 months you can start pulling all the plants including strings back out of the greenhouse, that's terrible in every way."

Around visiting the Canadian Greenhouse Conference, Robert and colleague Glenn will again visit many growers. "We are still working a lot with the early adopters. Our product is becoming better known, but there is also a lot to gain."

Partly because growers have been introduced to other products in the past, which turned out not to work, he notes. "There are also 'ordinary' ultrasonic transmitters. With these, you don't kill off viruses, bacteria, and fungi. That image sometimes still drives us nuts, which is why we stress every time that cavitation makes the difference."

Local presence

To grow, Ultramins is looking for local partners. In some markets, these have already been found. Despite the help of distributors, Robert still chooses to regularly visit his team himself. "We do that to know what's going on. Besides, having a local presence creates trust. In addition, we see many growers first start in the basins and after those results are good, ask us to treat the silos and drain as well."

Traveling is not necessary for installing the product. "We don't actually speak of installing but of placing. The grower can actually always do that himself. For one silo, it takes 15 minutes. A larger basin with several emitters takes a bit longer, but it's not difficult. Even I can do it," laughs the Dutchman.

"The big advantage is that existing irrigation systems do not need to be modified. You simply place the transmitters in existing basins, silos, or underground wells. With the installation of just one transmitter, existing UV systems tend to start working better because the water becomes clearer and contains less organic material. Ultrafiltration machines can also benefit because the membranes require less rinsing."

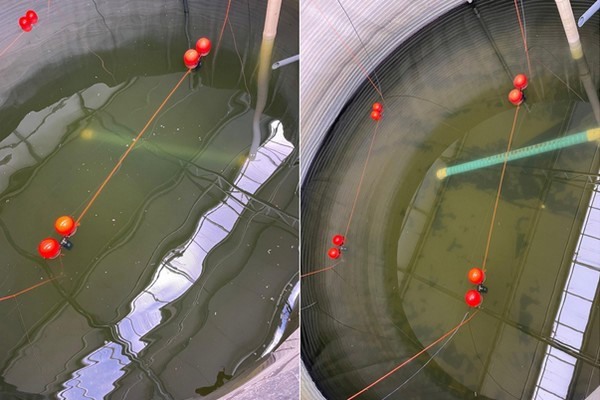

Before and 2 days after treating the water in the silo with USAF™ cavitating ultrasonic transmitter at C&B Farms in Leamington, Canada

Positive reports

After installation, the rule is 30 days no good, money back. "For us, it is no longer a question of whether it works. We have tested so much and also have so much practical experience that we can offer this service. Moreover, we also hear from customers that they have sometimes recouped the investment within six months. Our product works quickly after installation. For example, growers see the virus decreasing rapidly. Especially in cucumbers, this is quickly visible."

Despite now having the necessary international horticultural experience, Robert is "still learning every day". "What I like is when we get reports back from growers who initially had a lot of misery, but whose water is now good. Those growers see their yields increase again. Our goal is to enlighten growers. Growers already have so much work on their plates. I've noticed that in recent years. If they can exclude their irrigation water as a cause, that gives them peace of mind and they can focus on other things. Because a problem can have multiple causes."

Luxury situation

Over the next few years, Ultramins expects rapid growth. A lot has been invested in awareness of the product. The team has grown to around 7 FTEs, there is an external call center that Ultramins works with to make appointments for the consultants and Robert is also looking for experts in the field of marketing and communication to grow his business.

Growing the business is still done from North Holland. Will it stay that way? "Yes, we have a local presence, but we are not going to settle there any time soon. Digitally, we can also support our customers very well." And isn't he then afraid of growing too fast, as water seems to become increasingly important for international horticulture? "I hope we continue to grow well, and luxury situations can always be financed."

Growth outside horticulture

The water technology company is not only growing in horticulture, by the way. USAF cavitating ultrasonic transmitters can also be used in other sectors where water quality is important, such as fish and shellfish farming. With the help of business development manager Eric van Velzen, Ultramins is exploring new markets.

Markets from which the company is also learning new things. "In horticulture, in addition to our transmitters, growers often work with dosing a little hydrogen peroxide or another product. Growers are going to save on the use of additives anyway when using USAF cavitating ultrasonic transmitters."

A few in horticulture are already working entirely without additives, Robert observes. "With increasingly stringent regulations, worldwide, the demand for more sustainable solutions is increasing. Our goal as a company is to contribute to this as well because the use of chemicals will have to be increasingly limited."

In fish and shellfish farming, Ultramins' solution uses no chemical additives. "At the moment, extensive testing is taking place with the use of our transmitters at a shrimp farm in Southeast Asia. The initial tests here also look very encouraging. All in all, in my view, what we offer is really a silver bullet for many markets where water storage is problematic. "*

*A silver bullet is something that solves a serious problem very quickly and easily

USAF™ is a trademark of Luijkx Ultrasound B.V.

For more information:

Ultramins B.V.

+31(0) 85 023 10 97

info@ultramins.com

www.ultramins.com