Using a high-pressure fogging system can result in a lower plant temperature, enabling growers to use the screen less during the summer period. This conclusion comes from trials conducted in a 16-hectare bell pepper greenhouse in Canada.

Data-driven decision-making

What does high-pressure fogging do to a crop, and how can data-driven decision-making play a role in this? The teams from LetsGrow.com and MJ-Tech began a collaborative research project to quantify their expectations. In 2023, they set up a study comparing two identical compartments in the same 16-hectare bell pepper greenhouse in Canada, with both compartments experiencing the same outdoor conditions and plant growth stages. The key difference was the installation of an MJ-Tech high-pressure fogging system in compartment 3, which was controlled by a Hoogendoorn climate computer. Both compartments utilized Intelligent Ventilation from Hoogendoorn Growth Management's Intelligent Algorithms to optimize climate conditions, enhance photosynthesis, and increase fruit weight and production by balancing energy, water, and assimilates.

The first results already showed the fogging system increased humidity levels while decreasing the greenhouse temperature in the misting compartment. Over the summer, it also became clear that due to the lower plant temperature in the misting zone, the screen was used less, based on the advice of specialists from MJ-Tech and LetsGrow.com. This decision was made to allow more solar radiation to penetrate the canopy and increase the conversion efficiency from light into assimilates.

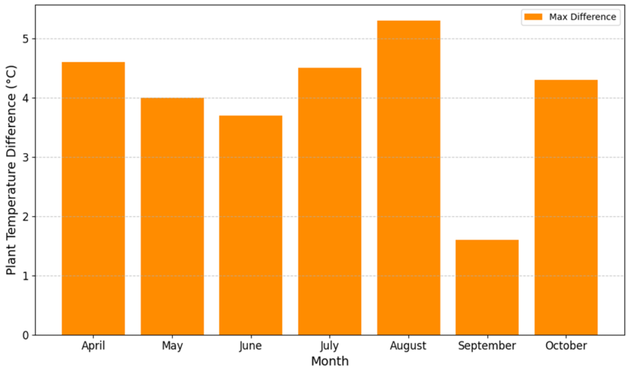

Figure K. Maximum plant temperature difference (°C) between compartments 1 (non-misting) and 3 (misting) during periods that the high-pressure misting system was active. Plant temperature in the misting zone is lower during the growing cycle.

Enhance phytosynthesis

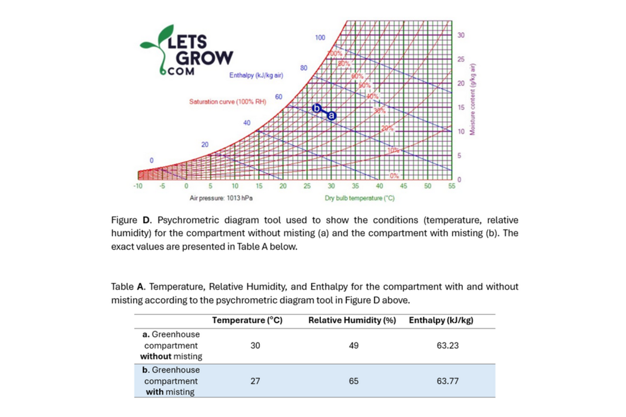

Rob Kwinten and Nicole Kuleshova of MJ-Tech explain how this system aimed to enhance photosynthesis and transpiration, improve water-use efficiency, and prevent water stress by ensuring moisture evaporates before reaching the plants. The Mollier diagram, which illustrates the relationship between water vapor content and air temperature, was a vital tool in this regard. Similarly, the Psychrometric Chart, available in the LetsGrow.com online tool, displayed changes in humid air conditions.

"The high-pressure fogging system worked by injecting 3 to 5 micron-sized droplets at 100 bars into the air, facilitating the transformation from liquid to gas, thus increasing humidity and lowering temperature in the greenhouse while maintaining the same enthalpy levels," Rob explains.

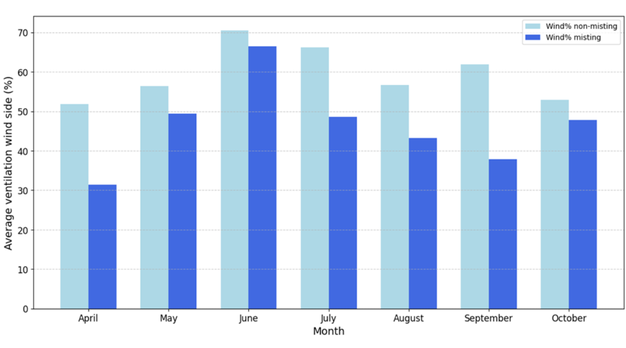

Figure H. Average ventilation wind side (%) for 1 (non-misting, light blue bar) and 3 (misting, dark blue bar) during periods that the high-pressure misting system was active.

Figure H. Average ventilation wind side (%) for 1 (non-misting, light blue bar) and 3 (misting, dark blue bar) during periods that the high-pressure misting system was active.

Consistent decrease

The misting compartment showed a consistent decrease in wind ventilation, referred to as 'squeezing the vents,' with an average wind ventilation percentage difference of 13.1 ± 5.9% between the misting and non-misting compartments. The plant temperature in the misting compartment was also lower, with an average difference of 0.8 ± 1.2°C. The screening strategy remained identical for most of the cultivation period, with differences only occurring during late summer when the misting zone used the screen less, allowing more solar radiation to penetrate the canopy. The maximum plant temperature difference observed was up to 5.3°C, and the maximum difference in total ventilation rate was up to 24.02%.

"This demonstrates the benefits of combining Hoogendoorn's IIVO climate control, data analysis, and monitoring from LetsGrow.com with MJ Tech's high-pressure fogging system, which, among other benefits, allowed the team to achieve the optimal balance between greenhouse temperature and humidity levels" add Alexandra Skouria and Evripidis Papadopoulos from LetsGrow.com.

Following this research, further studies are ongoing. This year, the trials focus on screen strategies, the use of Intelligent Algorithms (for example, in ventilation management), irrigation data (such as drainage and water uptake), and, of course, crop data.

The complete whitepaper "From Theory to Practice: Optimizing Photosynthesis via High-Pressure Fogging Using Data-Driven Growing at a Canadian Pepper Greenhouse - Deep-Dive into Ventilation, Screening Strategy, and Steering on Plant Temperature" can be downloaded here, or can be found at the LetsGrow website.

For more information:  MJtech

MJtech

Tel +31 (0) 76 597 45 03

[email protected]

www.mjtech.nl

For more information: LetsGrow.com

LetsGrow.com

[email protected]

www.letsgrow.com