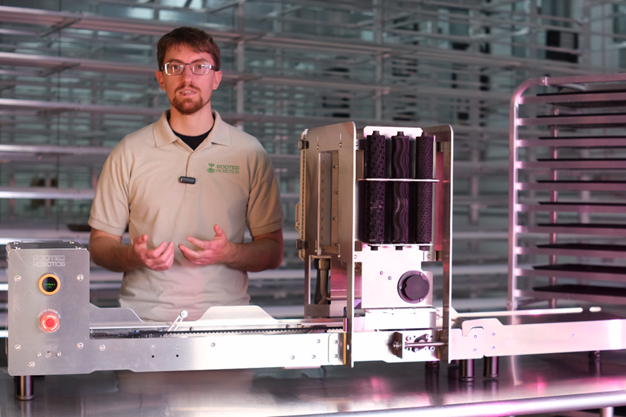

"For a smaller farm, spending $100,000 on one process doesn't make sense when there are 10 other processes that need to be done. The high cost of automation systems in vertical farming and hydroponic greenhouse growing has long been a barrier for small to medium-sized producers. While large-scale operations can afford advanced equipment, smaller farms often struggle to justify the hefty price tags. We wanted to push the industry forward by lowering the barrier to entry for automation," says Max Knight, Co-founder of Rooted Robotics.

Maximilian Knight and the Tabletop Microgreens Seeder

Maximilian Knight and the Tabletop Microgreens Seeder

Max is on a mission to address the issue by creating affordable, customizable machines tailored to the needs of small- to medium-sized vertical farms. A great benefit for Rooted Robotics is the experience of Max's co-founder Eric Roth, who has over 15 years of experience growing microgreens, lettuce, and more at large and small-scale indoor farms like Kalera, Farmed Here and his aquaponics farm Greens and Gills. It's critical to understand the growing pains of operators, as Max affirms.

"The demand for affordable automation is high in North America. In Europe, the different standards for trays and cultivation methods for smaller farmers make it challenging. However, we're gaining more traction and are working on adapting to those needs."

Affordability at the center

Many existing automation systems are, typically, designed for large-scale operations, leaving smaller farms with fewer options. Max and his team identified an opportunity to provide automated solutions at a lower price point, enabling small businesses to reap the same benefits of automation. "We're targeting farms that harvest roughly 100 to 1,500 lbs (45 – 680 kg) of leafy greens or microgreens weekly. At this scale, our machines make economic sense."

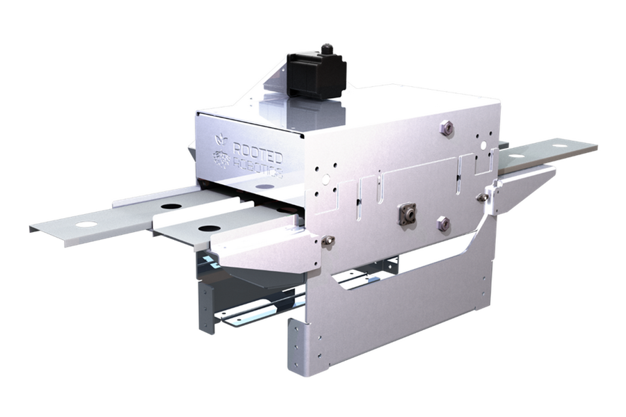

The Leafy Greens Harvester

"We focus on ROI. Our machines aren't just affordable, they're designed to deliver yield improvements and labor savings that quickly pay for themselves," Max explains. For example, their microgreen seeding machine, priced at $7,000, ensures consistent seed distribution, leading to better yields. "The seeding machine might not save much on labor, but yield improvements from even distribution are huge. It's these hidden benefits that add up," Max adds. Their leafy greens harvester costs $25,000, and are currently developing a smaller, tabletop version to meet the needs of even smaller farms.

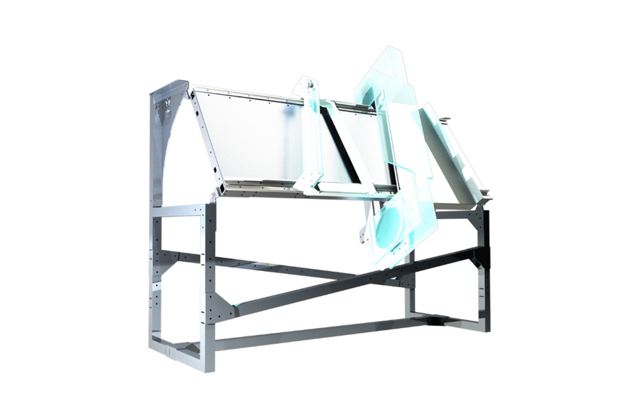

The NFT Channel and 1020 Tray Pressure Washer

Plug-and-play

The machines are built using many off-the-shelf components, making maintenance easier and cheaper for farmers. "Since we design the machines with easy-to-replace parts, farmers can easily fix it themselves in case something breaks. This helps reduce downtime and bottlenecks, which is a huge cost for small operations," Max explains.

While Rooted Robotics' machines are primarily designed for microgreens, they also work for other crops like leafy greens. Their harvesting machine, for example, is adaptable enough to handle multiple types of produce. "We're developing a washer that can run 1020 trays or NFT channels through it. We want our machines to be flexible so farms can adapt them to their needs. On top of that, our machines are upgradeable, like our harvester, which can work on its own or be integrated into a conveyor belt system, depending on the farm's needs. "In addition to our machines, we work with farmers and investors on feasibility studies, farm design, and custom machinery."

The company has raised over $650,000 from grant funding as well as investors and is currently in discussions with investors for their next funding round.

"Our mission is to accelerate the adoption of controlled environment agriculture, and we're just getting started," Max concludes.

For more information:

For more information:

Rooted Robotics

Max Knight, Co-founder and CEO

www.rootedrobotics.com