Annually in April/May, the Dutch Seaweed Group harvests tons of seaweed at once from the Oosterschelde. Seaweeds have a seasonal cycle, so unfortunately, more frequent fresh harvesting is not possible. However, this can be done in a greenhouse. Therefore, the Zeeland seaweed specialists are busy making a combination of sea and land-based seaweed production. Meanwhile, drying (or pickling) harvested seaweed is a solution to extend the shelf life of seaweed. A new state-of-the-art dryer has been operational for half a year for drying.

"We can dry a ton of seaweed daily, but we don't do this all year round," explains general manager Alwin Kool. "Therefore, we are happy to offer our dryer for drying other products, such as other sea vegetables, but also herbs or even peppers."

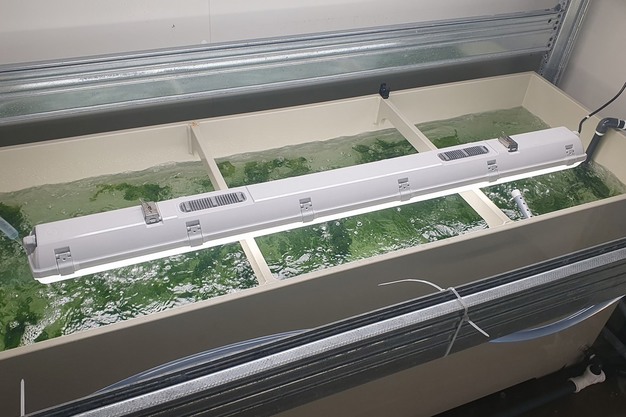

Inside the new dryer in Yerseke.

New dryer

Drying seaweed has been a practice at the company, where forces were joined with Seaweed Tech at the beginning of 2023, for a long time. However, a previous drying machine did not work optimally. "We paid our dues for that. This is a completely different system, for which we used all our knowledge and experience."

The dryer is located in the factory hall in Yerseke where further seaweed processing takes place. There, the drying process occurs. "A condensing heater blows hot air from one side of a container through a wall in the middle. On the other side, we remove the moisture from the product, keeping the heat inside the container and thus keeping energy consumption very low."

Alwin (right) at a line for washing and blanching seaweed before it enters the dryer.

Demand from other products

Offering the dryer to external parties would be a win-win for the Dutch Seaweed Group. "The goal is to better utilize this energy-efficient dryer that otherwise would be idle for part of the year. This way, clients don't need to invest in this technology themselves. We also regularly receive inquiries from other parties about the status of our dryer."

Although the market for seaweed products is growing, it's not yet the case that seaweed is being dried year-round. "For example, we have already dried samphire for a client of ours."

A combination of seawater and greenhouse

Two and a half years ago, just before the merger with Dutch Seaweed Group, Alwin and his partner Michel Trommelen were already in the news due to their search for a greenhouse. That search has now finally yielded results. "The search for the combination of greenhouse and seawater has not been easy. We received many responses and spoke to many potential candidates, but the link between large-scale use of seawater and a greenhouse proved to be a too big challenge each time."

Until now, that is. "We have set our sights on a greenhouse in the port area of Ostend, Belgium. There, we want to run a larger pilot than we have been able to do so far. At the moment, we are already cultivating land-based seaweed on a small scale in Kamperland. Together with like-minded parties, and with subsidies from a Dutch-Belgian fund, we want to gradually scale up."

Land-based seaweed production in Kamperland.

Fresh market

Dutch Seaweed Group hopes to have clarity on the subsidy next month. "After that, we can start operating quickly and also want to be operational on land." The latter also brings a step closer to the fresh market. "For that, we need to be able to harvest more often than we currently can from the sea." Apart from the frozen or dried products, a step towards the fresh market has already been taken. "We already supply a salted product to a trading company. This product is thereby shelf-stable for three months."

There is a lot of development in saline agriculture. "The cultivation of microalgae is still ahead of seaweed cultivation, where you also have the production of microalgae in freshwater."

Seaweed cultivation on the Oosterschelde.

For more information:

Alwin Kool

Dutch Seaweed Group

[email protected]

www.dutchseaweedgroup.com