A simpler crop rotation than last year—who wouldn't want that? Less dirty water system facilitate crop rotation. This can be achieved by preventing algae growth and biofilm accumulation. It happens that growers are knee-deep in sludge when cleaning a silo. Or at least spend a lot of time cleaning silos and water systems.

Robert de Hoo of Ultramins is familiar with the images, which he sometimes receives on his smartphone. Especially during the crop rotation period but also at other times of the year.

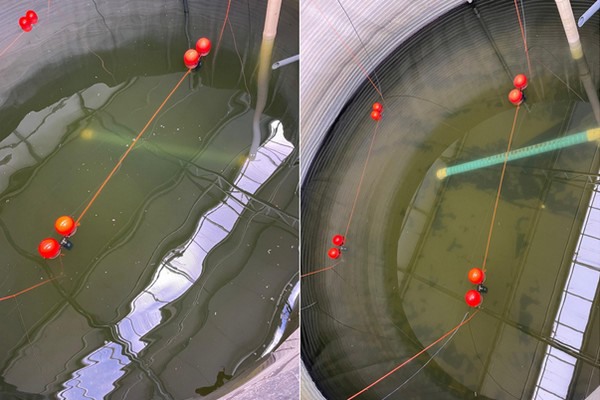

Before and 2 days after treating the water in the silo with USAF™ cavitation ultrasonic transmitter at C&B Farms in Leamington, Canada

With the USAF ultrasonic cavitation transmitters that the company provides, growers can prevent such dirty silos, he emphasizes, pointing to the photos. He is also pleased to increasingly receives photos from growers who are experiencing the benefits of Ultramins' products: clean basins, silos, and water systems.

Before and after at Spring Valley Gardens in St. Catherine's, Canada

Before and after at Spring Valley Gardens in St. Catherine's, Canada

Jeremy van Koeveringe from Spring Valley Gardens in Canada: "Ultramins visited us on our greenhouse operation, and at that time I was dealing with an algae issue in our water basin. The low EC value combined with the hot weather resulted in algae growth that was out of control. After placing just 1 USAF™ transmitter in our 2.000m2 pond, the algae disappeared in a few weeks. The water became crystal clear and the vertical visibility improved to more than 2 meters."

Impressed by the results, the grower ordered 7 more transmitters, and installed them in various cisterns and silos at all three of their locations. "I've been very pleased with Ultramins product and support, and I confidently recommend their transmitters to all growers."

Jeremy van Koeveringe, Spring Valley Gardens

Jeremy van Koeveringe, Spring Valley Gardens

"Saves a lot of hassle"

Aside from the advantage during crop rotation — easier and less labor-intensive cleaning —the use of the ultrasonic cavitation transmitters has also proven itself during cultivation. For example, at The Mastergrowers, Dutch ornamental growers. Robin van Dijk says: "At one of our locations, we have an uncovered silo of 1,000m3. This silo had many problems with algae growth and there were also multiple pathogens present, including a high degree of Pythium and Phytophthora. Due to the algae, we had to clean the filters often, which was quite time-consuming.

After hearing very positive stories from a grower who had been working with Ultramins for a while, we also decided to do so, and we were pleasantly surprised. Aside from the fact that the algae growth and biofilm quickly disappeared from the silo, we noticed that the fungal pressure had also decreased enormously. More than 95% was gone in 2 weeks while we used just one USAF ultrasonic transmitter.

Soon we bought a second transmitter for one of our indoor silos, this will certainly not be the last transmitter we buy. The results are excellent, these transmitters are easy to use and save us a lot of time and money. It also significantly reduces the amount of labor needed, and it saves a lot of hassle."

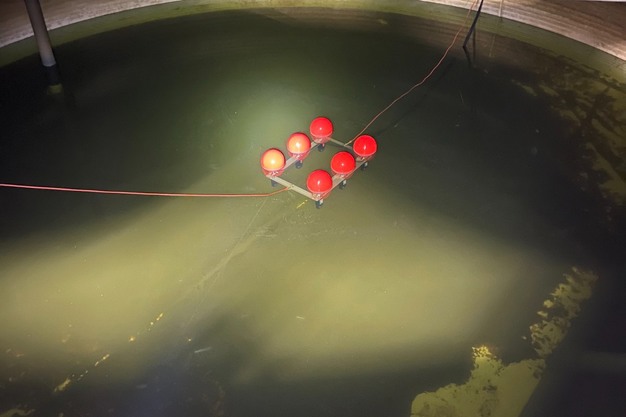

The USAF™ cavitation ultrasonic transmitter in action at Greenhill Produce in Kent Bridge, Canada

The USAF™ cavitation ultrasonic transmitter in action at Greenhill Produce in Kent Bridge, Canada

USAF™ is a trademark of Luijkx Ultrasound B.V.

For more information:

Robert de Hoo

Ultramins

Jelle Zijlstraweg 45

1689 ZX Zwaag

The Netherlands

+31 (0) 6 20 536 536

+31 (0) 85 023 10 97

robert@ultramins.com

info@ultramins.com

www.ultramins.co