"This high yield demonstrates the potential of AI in agriculture, particularly in improving resource efficiency, crop yield and reducing the need for continuous human oversight," said Kenneth Kenneth, who is now the CEO of Koidra, a provider of intelligent greenhouse automation using AI.

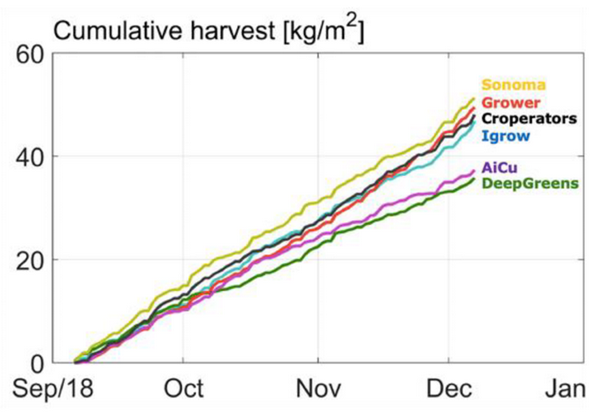

In 2018, a team led by Kenneth placed first at the inaugural Autonomous Greenhouse Challenge with a yield of 51.25 kg/m2 in less than four months. At the time, Kenneth worked at Microsoft Research on real-world reinforcement learning research, focusing on applications in data center energy optimization and controlled environment agriculture.

The team's win at WUR's first Autonomous Greenhouse Challenge served as a significant step forward in exploring how technology can be integrated into traditional growing practices. It also played a key role in the founding of Koidra.

Dr. Kenneth Tran (second from left) led Team Sonoma, which won the first International Autonomous Greenhouse Challenge by successfully growing greenhouse cucumbers in the Netherlands for four months while operating remotely from Redmond, WA.

The challenge, organized by Wageningen University & Research in the Netherlands, was the first time cucumbers were grown remotely using artificial intelligence. Five international teams representing nine countries were required to cultivate cucumbers within a 96-square-meter space. The goal was to maximize net profit and minimize resource use.

A sixth greenhouse compartment was controlled by experienced Dutch growers and served as a reference.

Each team remotely controls actuators (for heating, ventilation, screening, lighting, fogging, CO2 supply, water, and nutrient supply) using AI algorithms. These varied among teams, leading to different cropping, climate, and irrigation strategies, as well as varying yields and resource use efficiencies.

Kenneth's Team Sonoma stood out by focusing on a high daily light integral while optimizing artificial light, temperature, and CO2. They achieved the highest yield and maintained efficient light use.

Team Sonoma achieved the highest yield among the 5 teams competing at the Autonomous Greenhouse Challenge 2018.

Besides having the highest yield, Team Sonoma beat all other competitors in profit and sustainability. Compared to the reference grower benchmark, their net profit gain was 17%.

AI's growing role in sustainable agriculture

Integrating AI into controlled environment agriculture marks a new era in crop production. The journey of AI from theoretical exploration to practical application is still in its early phase. However, the data emerging from studies and trials continues to show positive signs.

The implications of AI extend far beyond increased yields and efficiency. It plays a crucial role in supporting a complex decision-making process that is adaptable to farms of all sizes and experience levels.

Expert growers, armed with AI tools, can now more effectively train new growers and establish standard operating procedures, ensuring a higher standard of growing practices across the board. This technology also empowers new growers, providing them with the tools and confidence they need to make informed decisions in the agricultural process.

Additionally, AI aids growers in adapting to and learning new crops, a previously time-consuming and risk-laden process. This rapid adaptability is crucial in today's agricultural landscape, where market demands and climatic conditions are always changing.

From a financial perspective, the benefits of AI in agriculture can be quantified in two significant ways: an increase in revenue per square meter per year and savings in expenses per square meter per year. The former is achieved through higher yields and better-quality produce, which command a premium in the market. The latter is realized through more efficient use of resources, such as water, nutrients, and energy, leading to substantial cost reductions.

These financial returns are not just hypothetical. They're being actively demonstrated in real-world applications, as seen in trials and collaborations between AI companies such as Koidra and large-scale growing operations.

Applying autonomous control in cucumbers as part of the AGROS project

Ongoing development of AI-driven cucumber greenhouses

Currently, WUR continues to explore autonomous greenhouse systems through its AGROS project. The primary focus is on creating an autonomous cucumber greenhouse where cultivation is remotely controlled using AI. This project integrates intelligent algorithms and advanced sensors to monitor key crop characteristics, supporting decisions for profitable cultivation.

A validation trial concluded in August this year. The experiment involved growing Hi Power cucumbers in three greenhouse compartments using different methods. One compartment was controlled by growers using traditional methods, while the other two used AI algorithms — a Digital Twin and a Reinforcement Learning (RL) algorithm.

- The growers' compartment, which operated based on current grower knowledge and best practices, achieved the highest net profit. This proved the effectiveness of traditional expertise in cultivation and irrigation strategies.

- The Digital Twin compartment, which simulated crop and climate responses, used real-time data to balance costs and benefits. While it produced fewer cucumbers, it was efficient in electricity usage, leading to the lowest cost per kWh of electricity.

- In the RL compartment, the algorithm controlled climate autonomously, adjusting factors such as lighting, CO2 concentration, and heating. Despite not being trained for irrigation and fruit pruning, it adapted well to temperature fluctuations and showed good fruit production.

"This trial confirmed that autonomous control systems, such as Digital Twin and RL algorithms, can effectively manage greenhouse environments," said Anja Dieleman, AGROS project leader and researcher at WUR's business unit, Greenhouse Horticulture. "The next steps involve integrating continuous, automated data from climate and crop sensors to enhance these systems."

GLG achieved a 19.6% yield increase in cucumbers by using Koidra's autonomous growing solutions

GLG achieved a 19.6% yield increase in cucumbers by using Koidra's autonomous growing solutions

On the commercial grower side, last year, Koidra teamed up with Great Lakes Greenhouses Inc. (GLG), one of North America's largest greenhouse operators, to see how much yield increase is possible with an autonomous cucumber greenhouse.

Koidra applies its innovative solutions, including the DataPilot and KoPilot systems, to optimize growing conditions at GLG. DataPilot plays a crucial role in this process by integrating and managing large datasets, which are essential for informed decision-making. These datasets, stored on the cloud and visualized on a dashboard, provide a comprehensive overview of the environmental conditions.

Meanwhile, KoPilot, drawing insights from this data, makes real-time decisions and sends setpoints back to the climate computer. This allows for dynamic adjustments. The synergy between DataPilot and KoPilot enables the system to adapt seamlessly to changing conditions and optimize operations dynamically, ensuring an optimal growing environment at all times.

The trial lasted three months and resulted in a 19.6% yield increase when compared to the controlled zone operated manually by expert growers. At the same time, GLG reduced its unit electricity cost by approximately 17% in the AI-controlled zone.

The yield improvement was achieved through 24/7 control of temperature, humidity, and CO2 levels. No additional lighting was used.

"With optimization, we're always a yield-first focus," said Mark Reimer, GLG research and business development manager. "But when we can add a percentage of yield increase while not increasing our greenhouse footprint, that's where we benefit from this technology."

For more information:

For more information:

Kenneth Tran, CEO and Co-Founder

Koidra

hello@koidra.ai

www.koidra.ai