"The impact of AI in CEA is expected to add 100% more efficiency. Full control can help plants become more nutritious, offering a finer flavor and allowing growers to forecast better. The main reason that we don't have this 'a super brain for farming' today is due to a lack of data. What's needed is high-quality data to witness what environments affect different plants," shared Robin Johansson, COO at Optima Planta during the CEA 4.0.

Founded by Lennart Sör in 2017, Optima Planta has ever since set its sentences on optimizing vertical farming using bio-informatics, IT, and AI. The Swedish startup is based in Uppsala, where its R&D facility is located.

Robin Johansson and Lennart Sör pictured at the Uppsala facility

'Lack of high-quality data in CEA'

As Robin went on to explain, there are thousands of years of accumulated farming experience, but most of that throughout history has been outdoors. Then there is data about indoor farming, yet, even if the environment can be controlled, there's generally a homogenous environment for the entire facility. Meaning that you'd obtain one set of relevant data per harvest session.

Nevertheless, data is used today and is already very valuable. "We can see that the anomaly detection in plants is already used, e.g., As it's fairly simple to set up cameras and take loads of photos of healthy and unhealthy plants."

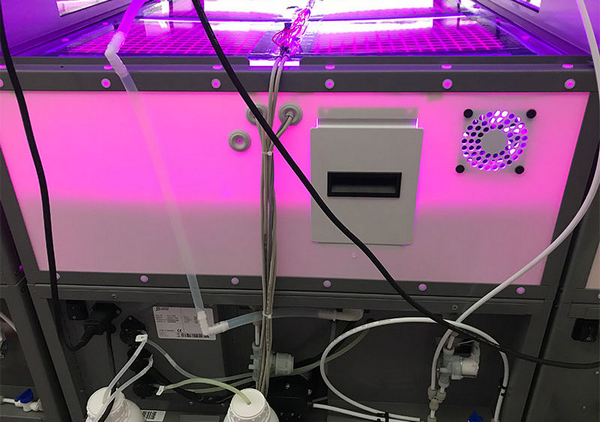

ADA Boxes

As Optima Plant figured this was a gap to fill in the market, they started creating modular systems that are used for R&D or commercial purposes. ADA, the Agriculture Data Assistant, is a technology that helps narrow down what environment is best for what plants. It also aids in answering various types of questions related to that. "We've seen that in a 25-50% difference in yield within different recommended parameters. It has a very big potential, really," Robin shares.

As for the device, it's rather resource efficient and automated to a high degree. Adding to that, the system is quite modular as it has its own environment. "Therefore, it's rather easy to divide the growing facility into how many different plants the market is requesting at a certain moment. Let's say starting with leafy greens, then apply roots or later add ornamentals to the system."

Outer looks of the ADA

A plug-and-play solution

All boxes are automatically controlled and have low variability, as users can see what has been happening and the potential changes that led to the different results. All stacks are EU pallet size, which is 80 by 120 cm and 250 cm tall. The top half of the box is about 30cm high, yet sizes are customizable on request.

The plug-and-play boxes are aeroponic-based as the company believes that this technique allows plants to grow faster and permits more data points per time unit. On top of that, it's, in general, more resource efficient, according to Robin.

On the inside, a combination of sensors are measuring elements like pH, humidity, temperature, and electrical conductivity. Combined with those sensors in every box, there is a system that can implement changes to the system and adjust the environment whenever. "Once a crop is settled in, it comes up with recommended parameters that the system will inform the user about."

Currently, the company is working with various universities in Sweden to constantly add new features to the device and optimize processes. "We're definitely looking for partners, customers, and investors to bring us to the next stage."

For more information:

For more information:

Robin Johansson, COO

Optima Planta

[email protected]

https://optimaplanta.com