High-intensity lighting plays a critical role in promoting plant growth and achieving optimal yields. However, selecting the right lighting system for your CEA facility can be challenging, as there are many different light quality, intensity, and efficiency metrics to consider. Photosynthetically active radiation (PAR), extended PAR (e-PAR), energy use (in watts), photosynthetic photon flux (PPF), and photon efficacy (PPE) are all important items to consider when making a lighting fixture decision.

Here, we explore the various lighting metrics essential for CEA and their impact on the growth and development of indoor- and greenhouse-grown crops and the financial sustainability of your operation.

Light quality metrics for CEA operators

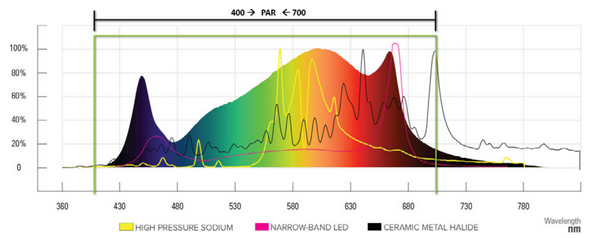

Light quality is determined by the relative amount of blue, green, red, far-red, and other spectra emitted from a light source. By delivering certain amounts of photons from a particular part of the light spectrum, CEA cultivators can create different morphological and secondary metabolite reactions within their crops.

PAR

Traditionally, the spectrum of photosynthetically active radiation (PAR)–which refers to the portion of the light spectrum that plants use for photosynthesis–ranges from 400-700 nanometers (nm) and encompasses photons in the blue (400-500 nm), green (500-530 nm), yellow/orange (530-600 nm), and red (600-700 nm).

“What I advise growers is, if you are not looking for specific morphological traits, then I would go for a fixture that is providing more of a white light,” advises Dr. Roberto Lopez, Associate Professor, and Controlled Environment and Floriculture Extension Specialist at Michigan State University. White light, which is a more normalized color distribution, is “easier on your employee’s eyes as well as it’s easier to identify physiological disorders, diseases, and insects,” he adds.

However, specific crops might require specific spectra to better express certain traits. For example, growing red-leaf lettuce under higher temperatures and white LED fixtures can reduce the expression of anthocyanins, the compounds that impart the red-purple color to plants. With red-leaf lettuce, Dr. Lopez suggests adding more blue light or lowering the air temperature in the last days of production to stimulate the production of the secondary metabolite.

Lopez warns that blue light can inhibit leaf expansion and plant height, so it is important to keep blue light to the final days of production or to combine it with red photons.

It follows that a fixture’s light quality is more important to consider for indoor cultivators, as greenhouse cultivators “have background solar radiation,” Dr. Lopez shares.

For more information on the impacts of specific light spectra on crop development, refer to Resource Innovation Institute’s Lighting Best Practices Guide.

e-PAR

For years, producers and researchers focused their efforts on the established PAR range. But recent work, especially from Utah State University, “has found that far-red radiation also contributes to photosynthesis,” Dr. Lopez shares. Far-red light is found in the 700-800 nm range.

According to RII’s Lighting Best Practices Guide, in the presence of shorter wavelengths, such as blue light, far-red photons enhance photosynthesis and increase extension growth, including stem length, plant height, and leaf size. Using the same red-leaf lettuce example, Dr. Lopez notes that “when you have an increased percentage of blue light, you’re going to end up with a very compact head of lettuce. If you wanted to get some stretch and bigger leaves, then adding that far-red light is beneficial.”

Now that we know that it does contribute to photosynthesis, far-red shouldn’t be ignored,” Lopez says. That said, more research is needed to fully understand the impact of far-red spectra on the production of all crops, notes Leora Radetsky, senior lighting scientist at the Design Light Consortium, a voluntary technical performance requirements organization. “As new metrics become of interest to scientists and potentially to growers, for example, e-PAR, we need standards organizations to do the consensus work necessary to define those metrics,” she says.

Download Resource Innovation Institute’s Lighting Best Practices Guide for more information, expert insights, and tips on everything that goes into creating an efficient and productive lighting system setup for CEA facilities.

Light efficiency metrics for CEA operators

Beyond light quality, a lighting fixture’s energy use is another crucial factor that plays an important role in a CEA operation’s sustainability and profitability.

Energy Use

This is a measure of the total amount of energy consumed by the lighting system over a certain period. It’s typically measured in kilowatt-hours (kWh) and can be used to estimate the operating costs of the lighting system.

However, a fixture’s energy use is not tied to its performance in plant growth or its ability to create any light at all. For example, a good portion of the energy used by high-intensity discharge (HID) lights is lost to heat production. The efficiency in converting watts to light is why light-emitting diode (LED) fixtures are becoming the CEA industry standard and are already established as such for crops such as cannabis.

Photosynthetic Photon Flux (PPF)

Photosynthetic Photon Flux (PPF) “is important because it tells you the overall value of PAR photons that are coming from that fixture,” says Casey Rivero, a cannabis solutions architect with LED-lighting manufacturer Fluence.

PPF indicates the amount of PAR light a given fixture can produce, calculated in micromoles per second (µmol/s). This does not mean it is the amount of total light your fixtures will produce (typically measured in lumens). Light sources intended to be used in CEA are graded on their PPF output, not their total lumen production.

Photosynthetic Photon Efficacy (PPE)

PPE is a light fixture’s ability to convert power from electric energy to achieve rated PPF when delivering light to your plants. The efficacy of light products is measured in units of micromoles per joule (µmol/J). “PPE is PPF over the amount of energy consumed,” Rivero says.

A higher PPE means that a lighting system is more efficient at delivering light to plants, while a lower PPE means that a lighting system is less efficient and may require more energy to achieve the same level of plant growth. By choosing lighting systems with higher PPE, CEA operators can reduce their energy consumption and operating costs while still providing the necessary light for healthy plant growth.

“PPE is important because it tells you how effective a fixture is at utilizing that energy in producing that photon, but that doesn’t tell you how efficient and effective it is relating to plant production,” Rivero notes.

For example, “higher red component fixtures can produce problematic responses in the plant at a higher light level” on certain crops, including a phenomenon known as photo-bleaching. “The lack of chlorophyll development is driven by the high red component in the higher intensity light,” Rivero adds.

Photosynthetic Photon Flux Density (PPFD)

PPFD is the number “of photons within the PAR range, measured in micromoles, that hit a given area (a square meter) of your plant canopy per second,” per RII’s Lighting BPG. While fixtures have a fixed PPF rating, PPFD can be manipulated through a number of factors, including by adjusting the distance between the fixture and crop canopy.

PPFD also can be fine-tuned on lighting fixtures that have adjustable dimming and spectrum, another important trait to consider when selecting a CEA lighting fixture. “We believe that there’s a great value for dimming not only for energy and cost savings but also due to the fact that you can use dimming to optimize the environment for different life stages and for different crops,” Radetsky says. “That’s important because LED products can last for a long time–we’re not just talking about a season or two, they might be there for 10 or 15 years. Dimming functionality gives you the ability to future-proof your installation as we learn more about how we can optimize lighting to benefit different crops.”

With dimming, indoor farm operators can better reproduce natural lighting conditions, simulating sunrises, and sunsets to reduce the humidity spike that occurs when the lights shut off. An added benefit of slowly turning on lights is decreasing the maximum energy load farmers put on the grid (and for which they are charged).

It is also important to note that a higher PPFD rating is not synonymous with higher performance. “We’ve seen a trend in terms of the higher PPFD that growers are utilizing,” Dr. Lopez says. “We’re seeing people go all the way up to 800 [and 1,500] micromoles. Is that necessary? It’s dependent on the crops that you’re growing, but for leafy greens, we have not seen that it’s beneficial.”

Light Uniformity

This metric measures the degree to which light is distributed evenly across the cultivation area. Uneven light distribution can lead to uneven plant growth and lower yields. Growers can determine a fixture’s light uniformity through the use of a light map “that shows whether you’re getting a uniform PPFD in the crop area. You want at least 80% uniformity,” Dr. Lopez suggests.

Where to find CEA lighting fixture data

Lighting manufacturers will often share the above metrics on product packaging and their websites. For third-party vetting, DLC offers a Qualified Product List (QPL), which offers CEA operators insight into the fixture’s “worst-case performance data,” Radetsky explains.

“One of the benefits of the QPL is that tested product data for horticultural lighting includes an image of the spectral quantum distribution, so you can see what the spectrum is. You can see what the shape of the beam is by viewing the product’s photosynthetic photon intensity distribution image,” Radetsky explains, adding that “many utilities use the DLC’s QPL to offer rebates.”

Lighting manufacturers whose fixtures have been included in the DLC’s QPL often will advertise that on their product’s page or packaging, but it’s still important to check that the product is listed on the QPL even if the DLC logo is found on the packaging. DLC verifies fixtures through the unit’s model number.

DLC updated its lighting reporting requirements on March 31, so there are fixtures that might no longer qualify for the non-profit’s QPL in 2024. “We’re asking for a lot more reporting on the controls and also on the application so people can see what the product is doing more granularly,” Radetsky says.

Rivero is a strong proponent of DLC’s work and shares that “if a fixture is not DLC listed, don’t even think about it because we don’t have third-party testing on it.”

RII’s PowerScore tool also can help CEA operators identify system inefficiencies and benchmark their facility’s performance against their peers. RII’s Lighting BPG also offers insights and tips on how CEA operators can maximize their lighting system’s efficiency and efficacy, in addition to noting the environmental control benefits of optimizing lighting.

For more information:

Resource Innovation Center

www.resourceinnovation.org