Austin Wrenn keeps his family farm growing in Zebulon (North Carolina) through innovative solutions and active research at NC State University. During his unique journey from student to president of the North Carolina Strawberry Association, Austin was grounded in his family's multi-generational farm, always focused on growing strawberries. After international experiences in Europe and Australia, he returned to North Carolina to jump-start his family farm and the strawberry greenhouse production industry in the Southeast.

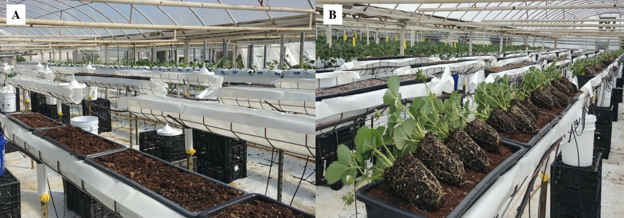

Most strawberry production in the Eastern US occurs in open-field plasticulture (Figure 1A). These systems require the use of fumigants and pesticides to remain productive. Climate-controlled greenhouses, however, need significantly less pesticide input (Figure 1B), less water, and labor and can lead to higher yields. However, transitioning into greenhouse strawberries requires high up-front costs, productive cultivars, and a highly skilled set of knowledge.

These are high barriers for the industry currently. But with increasing labor and supply costs, pesticide restrictions, and climate change, greenhouse strawberry production may be on the horizon to become a potential niche production system in the US in the years to come, full filling local market demands at times when other systems can't. One key component of strawberry greenhouse production is the use of soil-less substrates.

Farmer and recent MHS graduate Austin Wrenn is discussing his background and research on soil-less strawberry production in North Carolina. Video production and editing Amanda Lewis.

Figure 1. A. Open field plasticulture system for strawberry production (picture taken in North Carolina) is the predominant strawberry production system in the US. B. Strawberry greenhouse production (picture taken in North Carolina) faces a large set of challenges currently in the US, including high investment costs and a lack of expertise in the field. Photo credits: Amanda Lewis, Austin Wrenn, and Mark Hoffmann.

Figure 1. A. Open field plasticulture system for strawberry production (picture taken in North Carolina) is the predominant strawberry production system in the US. B. Strawberry greenhouse production (picture taken in North Carolina) faces a large set of challenges currently in the US, including high investment costs and a lack of expertise in the field. Photo credits: Amanda Lewis, Austin Wrenn, and Mark Hoffmann.

Six substrates

In Austin's master project, the impact of six different soil-less substrates on strawberry yield were evaluated on a day-neutral cultivar ('Albion'). Soil-less substrates included a 50:50 peat moss and pine bark mix, a 50:50 peat moss and coco coir mix, a 50:50 peat moss and perlite mix, a 50:50 peat moss and wood fiber mix, 100% coco coir, and a European peat mix (BVB) (Figure 2A).

Substrates were evaluated in a randomized complete block design in a tabletop growing system over a fall and spring double cropping cycle (2021/2022). Plants transplanted as 250cc tray plants (Figure 2B).

Substrate trials were established in plastic containers in a NC greenhouse. B. 250cc tray plants were used as planting material ('Albion').

Substrate trials were established in plastic containers in a NC greenhouse. B. 250cc tray plants were used as planting material ('Albion').

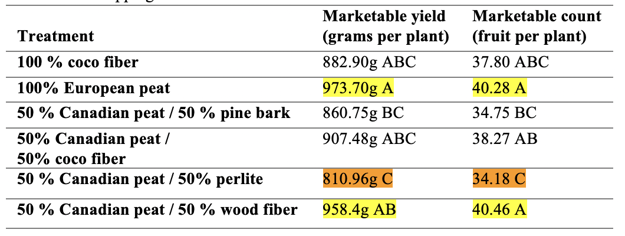

Marketable yields were assessed, as well as primary berry chemistry. Result highlights showed a significantly higher yield was seen in the peat moss and wood fiber mix, comparatively to the European peat mix, while the peat moss and perlite mix showed the lowest yield (Table 1).

Table 1. Marketable yield (g) and count of marketable berries per plant ('Albion') in the 2021-2022 double cropping season.

Table 1. Marketable yield (g) and count of marketable berries per plant ('Albion') in the 2021-2022 double cropping season.

Conclusions

While it is a long way for the Southeast towards a larger strawberry greenhouse production industry, Austin's research has pivoted him to use wood fiber/peat moss mixes in the next cropping cycle. Wrenn's farm was established in 1967 and grows strawberries since the 1980s. Today it has evolved to a cut-flower and strawberry operation, with a farm stand and value-added products. Research such as Austin's is essential to be better prepared for other strawberry-growing systems in the future. Young farmers like Austin are vital to the future agriculture business in the US. This research was partially supported by the USDA specialty crops block program and the North Carolina department of agriculture and consumer services.

For more information:

Mark Hoffmann, Austin Wrenn, Brian Jackson, and Amanda Lewis (video production and editing)

Department of Horticultural Science, NC State University.

Mark Hoffmann ([email protected])

Wrenn's farm

https://www.wrennsfarm.com/