A regular greenhouse is far from always the best solution anymore. Indoor farming gets a place in greenhouse farming. There is a future for indoor farms. Jilles Goedkegt, director of GreenV Indoor, says that in a year or two, it will be the mature solution for various crops. There are several examples of this in practice. A solution involves choosing the best cultivation result by default. They are the most efficient locations for ornamental and vegetable cultivation. Jilles states, "It is the ideal solution."

Does indoor farming still fall under greenhouse farming?

He laughs: "You have a point there. Yes, of course, plants are grown. And also, no, the more expensive labor and m2 of land become, the closer you get to indoor farming. Vertical farms lend themselves ideally to taking a lot of labor out of your hands. Cultivation will therefore become more factory-like. By extension, I expect autonomous growing to take off well in the area of vertical farming."

A cell of an indoor farm

From which area do you see the biggest development coming for indoor farming in the short term?

Jilles: "I currently see a wait-and-see attitude towards vegetable production in daylightless growing. A number of money-burning projects have come up. We must, as indoor farming suppliers, want to get the investments per m2 down. And that can easily be done. No doubt. When indoor farming just started, people started developing new growing recipes."

"In my opinion, that is not necessary. We already know so much. We know better than anyone else how to grow and what the plant needs. The parties that did that actually wanted to reinvent the wheel. That is not necessary and cost(s) unnecessary money. There is already so much, and it is already so good."

GreenV Indoor sees indoor farming picking up steam in the short term, especially from the corner of hybrid cultivation. Production sites increasingly want to grow their own indoors. Moreover, Jilles sees interest in indoor growing increasing from the ornamentals sector. Breeding now takes up about 10% of the area. Why not set up multilayer cultivation for that?

Left: rooting from an indoor farm. Right: rooting from a greenhouse.

Vertical farming allows you to grow strong plant material thanks to optimal controllability. This also seems to make it the ideal cultivation location for hardening off. The extra blue light further ensures stronger rooting and a compact plant.

"Indoor farming has a future. There is no doubt about that." Jilles points out that this cultivation saves labor and keeps out diseases and pests. The link to autonomous growing is then quickly made. "Because why would you want to grow autonomously in a regular greenhouse? How difficult do you want to make it for yourself? There are then so many extra difficult-to-control external factors hampering your crop. Unnecessary, in other words."

And the link to large-scale standardization in multilayer farming is also quickly made. There is some talk of changing existing buildings to indoor farming. "Too bad. You shouldn't want to make concessions on the technical side of an indoor farm. You get the best results by growing cells in an optimal format. These are precisely tailored to allow the crop to grow optimally."

GreenV Indoor frequently works together with Wessel van Paassen's Green Simplicity. Jilles Goedknegt and Wessel share the above opinion: Choose optimal results with an indoor farm.

Future

GreenV's subsidiaries are GreenV Indoor, Stolze, Prins Group, Prins USA, HT Verboom, Jan Voshol, and JV Energy. All these parties operate worldwide: Stolze in supplying technical systems, Prins Group in building and manufacturing greenhouses and integrated greenhouse projects, GreenV Indoor in daylightless growing solutions, HT Verboom supplies logistics systems, and Jan Voshol and JV Energy climate solutions.

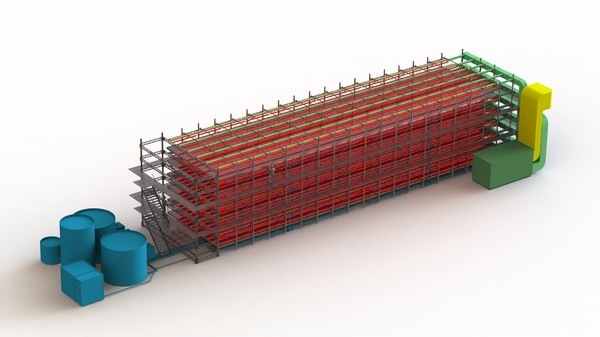

Drawing of indoor farming

Before signatures are made, they want to make visible in a business case that the entrepreneur chooses the best, most profitable solution. GreenV thus works on the numerical substantiation of projects.

Jilles points out that it can happen that a different solution is more suitable for the grower/investor than initially thought. "It won't be the first time that I am somewhere for an application for a vertical farm, and it turns out that a regular greenhouse is a better solution. But it also happens the other way around. As a group, GreenV wants to deliver projects as profitably as possible. And that is influenced by different factors like segment, climate, and crop location."

For more information:

Jilles Goedkegt

GreenV

Einsteinlaan 28

2289 CC Rijswijk

Tel.: +31 614 003 478

[email protected]

www.greenv.com