“Our fans help maintain an optimal microclimate and give growers more control over their crop,” says Mauro Pericoli with Termotecnica Pericoli. Now, the company launched its first fan made out of plastic and fiberglass: the ACF21p. “Thanks to the structure made of plastic, it has been possible to obtain optimized geometries to improve the aeraulic efficiency of the fan brings and also improve the loading possibilities.”

Termotecnica Pericoli has been creating climate solutions for greenhouses for over 55 years and has created many products in their R&D laboratory PERIlab. The newly developed ACF21p is the first fan they made out of plastic, with a high concentration of fiberglass. According to Mauro, it is the ideal product whenever air displacement is required. “Reducing the weight ensures high energy efficiency and excellent versatility.”

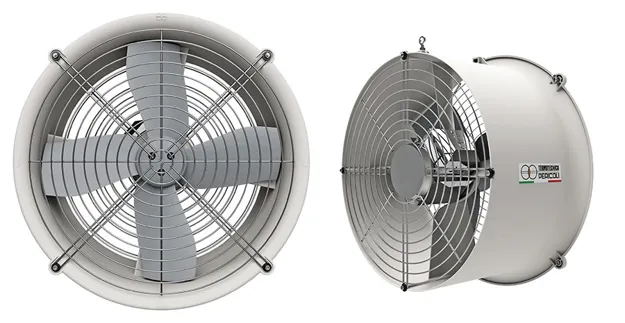

The ACF21p is available in 21”. Mauro shows how the fan body is monobloc with an embedded airflow stabilizer, a sturdy housing, and several hanging options. “The propeller is available with 3 or 4 blades and is made of plastic with a special impeller shape design. The safety nets are in galvanized steel for maximum corrosion resistance.”

Creating an air circulation fan of plastic brings several benefits, tests from the Pericoli BESS lab show. “Compared to the classic version, the performances have been improved again: there’s 19% more airflow for the 50hz and even 20% more airflow for 60hz”, Mauro shares, adding that the efficiency has also improved with 15% ccfm/W (cubic feet per minute) for 50hz and even 25% for 60hz.

The lower weight of the fan also improves the loading possibilities, which nowadays is very important for sustainability and cost matters. “In a 20ft container, we can load 38% more, in a 40ft container 36% more, in a 4ft HC container even 59% more, and on a truck, 71% more.”

For more information: Termotecnica Pericoli S.r.l.

Termotecnica Pericoli S.r.l.

Regione Rapalline 44

17031 Albenga (Sv) – Italy

[email protected]

www.pericoli.com