Strawberry production continues with peaks and troughs. That makes accurate harvest forecasting a challenge. To date, a margin of error of about 30 to 50 percent has been accepted.

Not surprising when you consider that growers still count manually and often not on a daily basis, Pieterjan Oomen points out. He is Product Manager, Designer, and Partner at YieldComputer. The company does count fruit using cameras on a daily basis and has also developed software to go with it. Now the aim is to develop towards a kilo prediction at daily level. The first growers are now testing this.

Paul Rooimans and Pieterjan Oomen at the International Soft Fruit Conference 2023.

Horticultural focus

BerryWorld launched the first version for harvest prediction in strawberries back in 2019. At the time, that was even with footage from a GoPro camera, Pieterjan remembers. "With that, we started collecting the first data." The strawberry growing and breeding company received the honor of the first pilot.

The founders of the Eindhoven-based startup, which is now on the verge of scale-up, had come into contact with Wil Beekers. Until then, they had looked to other sectors to solve problems with their technology based on artificial intelligence. Wil outlined the problem of crop forecasting to the tech companies. This put the focus for YieldComputer on horticulture and planted the seed for the harvest forecasting solution.

Inaccurate forecasts

YieldComputer quickly understood that harvest forecasting was a major challenge in the strawberry sector. Discrepancies of thirty to fifty percent between predicted volumes and realized volumes were and still are commonplace. This hurts both the grower's side and the side of trade and buyers.

"Inaccurate forecasts often result in a lower price per kilogram, with a surplus because the excess volume is sold at dump prices. Often a surplus comes unexpectedly, and retail cannot plan a promotion in time. In case of scarcity, they then have to buy again at high prices to get the volume sold."

Data-driven

YieldComputer offers a data-driven solution to optimize crop forecasts. Pieterjan: "Growers manually count fruit at the plant once a week, but often less. Manual counting is also done once per harvest. This is not enough and makes accurate predictions impossible."

Growers often have a lot of experience and knowledge, but that does not solve all the problems. "Comparisons with a warm period in a previous year are still often made to make an estimate, but this does not give an accurate picture of the current harvest. A warm period just two weeks earlier or later in the harvest curve or just slightly higher or lower temperatures matter. That's why we offer factual (historical) insights, and growers can combine these with their knowledge and experience."

The startup wants to reduce the deviation between prediction and practice to five to 10 percent. "We are already seeing optimization of the margin of error of up to 30 percent with our current solution with our current customers," it says. YieldComputer works with a performance-based pricing model. The grower pays a certain base fee and, on top of that, a fee as predictions improve. "Since we also want to offer real added value to the grower with our solution, they only pay more when the forecast is actually optimized, so they can also get their added value from it."

Steps have been taken in the past for crop prediction in strawberries. "Those attempts never really succeeded. Sometimes we notice that growers are still a bit reluctant because of this. In our eyes, when forecasting, often based on global historical data and weather forecasts, they were missing the local picture of the crop. We do have that. That is our distinguishing feature."

Climate station with camera

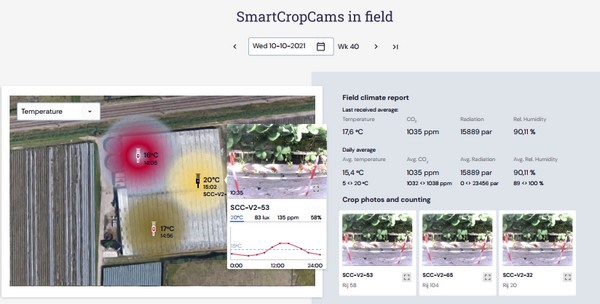

With data-driven software alone, YieldComputer sees gains to be made in the chain between cultivation and sales with more accurate forecasts. However, the company also offers a SmartCropCam. This autonomous climate station is important for optimal forecasting. The station measures temperature, relative humidity, CO2, and light. Moreover, the station is equipped with a camera that can be placed in both the greenhouse and outdoor crops. A minimum of four are needed per cultivation location. Depending on local conditions and the homogeneity of the field, more may need to be placed. "For example, in outdoor cultivation on a slope or with trees around it, where there is height difference and difference in sun and shade areas. These physical conditions may result in the need for more camera measuring stations."

That SmartCropCam takes the manual counting out of the grower's hands. A special camera foot has been developed for mounting the SmartCropCam. "It fits on almost all trays, pots, or gutters that growers use. In countries like Spain, we also use cameras for ridge cultivation. There, we put the camera in the bed with a pricker. We prevent leaves from growing in front of the lens with a rack around the camera."

YieldComputer deliberately chose its own climate measurement station. This means the company is not dependent on any necessary links to climate computers and has a grip on the data. The ability to link is there. The growers' data remains the growers' data. However, the model does gradually learn from the data to become smarter from it. "When moving from the greenhouse to outside, and thus from white soil film to grass, the camera was confused at first. The model saw strawberries in the grass. After retraining, that got better. It made our model more robust. The step to ridge cultivation with black plastic was easier after that."

Kilo prediction at day level

Seeing through leaves is not something YieldComputer's cameras can do either. "Our cameras take a picture of the crop every day. The fruit behind the leaf, we don't see. But that doesn't matter in our case because we can combine the photos with figures on the harvest achieved. We use feedback loops to correct this 'problem' in the data. Using the average fruit weight, among others, we can still calculate what the harvest will be."

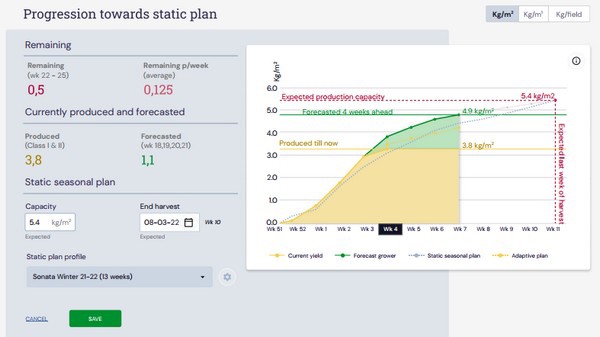

YieldComputer's forecasting model, which growers in the Netherlands, Spain, the UK, and Germany are already working with, works on the basis of trend forecasting. The ultimate goal is kilo prediction at daily level. "Last autumn, we piloted this," the Product Manager indicates. "In 2023, we want to roll out this model further to all growers we have been working with since 2019 and therefore have complete datasets from."

YieldComputer's forecasting model, which growers in the Netherlands, Spain, the UK, and Germany are already working with, works on the basis of trend forecasting. The ultimate goal is kilo prediction at daily level. "Last autumn, we piloted this," the Product Manager indicates. "In 2023, we want to roll out this model further to all growers we have been working with since 2019 and therefore have complete datasets from."

Interest in crop forecasting has been around since the market launch of YieldComputer. With the new step, the company is taking towards kilo forecasting, that interest will only increase, Pieterjan expects. "Interest is high, but we are still a relatively small company. We want to be able to give all the growers we work with our full attention. Next year, we expect to scale up quickly. Our software solution is already ready for the big roll-out. We are now optimizing our AI development."

In time, YieldComputer is also looking at other crops to predict the harvest. Raspberry is first in the picture in this regard. "For that, you do need different photos. Preferably, you photograph from below here to get a better view of all the fruits." Click here to enlarge.

Recent developments

Predicting the strawberry harvest was already not easy, but recent developments have not made it any easier. Cultivation schedules have started to shift even in strawberry cultivation. Moreover, lighting and heating are being reduced. Ever-bearing varieties are popular. "We also look at temperature but mainly use that data to make adjustments and calculate differences," indicates the Product Manager. "Unlike in tomato, where crop forecasting is also developing, strawberry is not nearly as constant. Instead, in strawberry, we also look at changes and calculate the impact of these."

YieldComputer's data-driven solution is now mainly set up for June carriers. A lot of experience has been gained in that. "There is still a lot unclear about ever-bearing varieties." Pieterjan knows that it even involves a microscopic examination to gain more insight into the crop. "We are currently still working with a generic forecasting model, but we are looking at market developments."

For more information:

Pieterjan Oomen

YieldComputer

[email protected]

www.yieldcomputer.com