If you choose to grow in a controlled environment, like a greenhouse, one of the most important equipment decisions you will make is deciding on the right HVAC(D) system. In this article, Ceres Greenhouse Solutions will discuss what makes an HVAC(D) system energy-efficient and why you should consider an energy-efficient HVAC system for your operation. But before we get into that, let's introduce a sealed greenhouse design and explain the relationship between an HVAC system and this design concept.

What is a sealed greenhouse, and why does it need an HVAC system?

For some growers, depending on crop type or external weather conditions, it has been determined that "sealing" the greenhouse (not allowing the greenhouse to intake, vent, or interact with exterior conditions) is the most effective way to achieve an optimal grow environment for their plants. With a sealed environment, growers can precisely control temperature, humidity, and CO2 concentrations for optimal plant health. It also allows cultivation facilities to protect themselves from exterior pests and pathogens that can limit or destroy harvests.

When a greenhouse is sealed, it becomes a "solar oven." Without appropriate cooling and dehumidification, a sealed greenhouse will overheat very quickly when the sun shines, regardless of the season. It will also become incredibly humid and will reach the point of saturation every cold evening, with water condensing throughout the greenhouse spaces.

Thus, the installation of an HVAC system is imperative to heat, cool, and dehumidify the sealed greenhouse space to make it suitable for plant growth. But not all HVAC systems are created equal. Let's get into what makes some systems more energy efficient than others.

Which HVAC system is the most energy-efficient?

This is the most common question we hear regarding HVAC systems. Unfortunately, the answer isn't that easy. To begin with, let's get a better understanding of what makes an HVAC system efficient.

In the most basic terms, an efficient HVAC system is one that can provide the most heating, cooling, or dehumidification with the least amount of energy input.

While energy type doesn't increase energy efficiency, we take this into consideration as well – leaning towards fully electric systems when appropriate. Electricity is the most desirable path forward regarding energy type because electricity can be created from renewable energy sources that these large mechanical systems can run on.

What makes an HVAC system energy efficient?

Many mechanical HVAC systems have an EER rating or Energy Efficient Ratio. This takes into account the BTUs created divided by the wattage used, or as stated before, the amount of heating or cooling provided divided by the amount of energy consumed. The higher the EER, the more efficient the equipment is.

IEER stands for Integrated Energy Efficient Rating, which takes into account the same piece of equipment but running at different loads. Oftentimes HVAC equipment is more efficient when it isn't running at full capacity, and IEER takes that into account to offer real-life efficiency values.

How to choose an energy-efficient HVAC system

Many options are available when it comes to choosing the right HVACD system for your cultivation facility. "We are adding a "D" to "HVAC" here because, ideally, you want a system that has the capability to dehumidify your space as well. We have seen everything from large-scale residential air conditioners (not advised) to geothermal heat pump systems installed in greenhouses. Budget is a major factor in the decision-making process, but you get what you pay for. What might be more affordable upfront often ends up costing more when it needs to be constantly repaired or, more often than not, replaced," the Ceres team says.

What is the most efficient way to heat a greenhouse?

This is a common question, but according to Ceres, what surprises many people is that cooling loads and latent loads (removing water from the air/dehumidification) are the drivers that usually dictate the size of the HVACD system and thus, its efficiency. So, the main energy use in a greenhouse is cooling and dehumidification. That being said, heating is still necessary in most greenhouses in the colder months.

In most regions, natural gas is currently the most cost-effective way to heat a greenhouse. "However, as we stated earlier, heat pump technology heats very efficiently with electricity as the fuel source instead of gas. This is possible because heat pumps transfer heat instead of converting it from combustion, which we prefer."

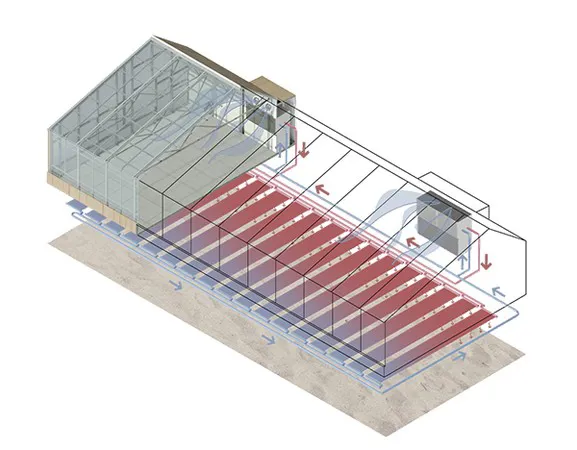

Sealed Greenhouse CEA – EcoPack or EcoLoop

Ceres Greenhouse Solutions offers two styles of HVACD (Heating, Venting, Air Conditioning, and Dehumidification) systems for the SunChamber (our sealed greenhouse design). The first offering is the Ceres EcoLoop, a ground-coupled hybrid system combining ground loops for heat exchange, evaporative cooling towers, and water-source heat pumps. The newest offering is the Ceres EcoPack, which is a packaged heat pump unit without the ground coupling (geothermal) addition of the EcoLoop. Both of these systems are very efficient and have the ability to heat, cool, and dehumidify, but the equipment and installation between the two systems are quite different.

Similarities

Heat pumps

The EcoLoop and the EcoPack are both heat pump systems. The EcoLoop is a water-source ground-coupled heat pump, whereas the EcoPack is an air-source heat pump. During the summer, they will pump heat out of the greenhouse to cool the growing environment; during the winter, the process reverses, and the heat pump will pump heat into the building to keep the space warm.

The EcoLoop is considered a water source heat pump because it has underground coils with water flowing through the loops providing heat transfer from within the greenhouse into the ground. The EcoPack is considered a packaged air-source heat pump because it can directly exchange heat with the external ambient environment and does not require a water loop installation.

"Both of the "EcoSystems," The EcoLoop and The EcoPack, can be ordered to run solely on electricity, which is beneficial as we transition into more renewable energies in an electricity-based world," the company explains.

Differences in hardware and functionality

The EcoLoop is composed of 3 main components that create the "system."

1. Water source heat pumps – The EcoLoop heat pumps are water-source ground-coupled heat pumps that use water as the medium for the heat rejection into the ground. When heating, the greenhouse warmth is extracted back into the building from the earth as needed for heating, and any excess waste heat will dissipate slowly into the ground.

2. Hyperloop – The EcoLoop utilizes geothermal heat exchange mats or coils buried 4 feet deep under the greenhouse. They are the components responsible for rejecting greenhouse heat into the earth, where it can be recovered for heating applications during the cooler months.

3. Adiabatic fluid cooler – The adiabatic fluid cooler provides an efficient alternative for heat rejection when the ground is saturated during the summer months when heating cycles are not required.

The EcoPack is a packaged HVACD unit and works quite differently than the EcoLoop.

1. Air-source heat pump – The EcoPack is a premium air-source heat pump that does not require ground coupling or water for heat rejection. Instead, it utilizes the ambient air outside the building for heat rejection during cooling mode and heat harvesting in during the heating mode.

2. Modulating compressors – The EcoPack has fully modulating inverter scroll compressors to provide precise load matching in the greenhouse with reduced energy consumption.

3. Modulating hot gas reheat – The EcoPack includes a fully modulating hot gas reheating coil to provide precision temperature and humidity control.

System differences

The main difference between the two systems is how heat is rejected or extracted from the environment to condition the greenhouse, either through water or air. As stated earlier, the EcoLoop uses water constantly moving through heat transfer products placed in the earth to store and dissipate heat to either cool or heat depending on the season, which adds to operational efficiency. The downside to the ground coupling is an increase in installation costs because of the added excavation and HDPE polyethylene pipe welding required during the foundation portion of the build. The EcoLoop is also reliant on the ability to evaporate water, so in humid summer climates or places that lack water as a plentiful resource, the EcoLoop may not be the best solution.

The EcoPack, on the other hand, can be configured only to require an electrical connection for installation, or it can integrate gas for heating and reheating functions. The EcoPack has a staggered coil design that will reduce supply air bypass and provide superior moisture removal from the greenhouse environment.

The EcoPack has an optional Economizer mode, which, if enabled, allows the system to intake filtered cool exterior air when select ambient conditions arise. This allows optional hybrid venting to lower greenhouse energy consumption to save even more energy.

For more information:

Ceres Greenhouse Solutions

www.cerescann.com