Work began in 2020, funded by Innovate UK, bringing together Crop Health and Protection (CHAP), Small Robot Company, farming enterprise AV, and N Lee to explore a new cost-effective and environmentally-friendly way to control the pests.

Now at its conclusion, the project has demonstrated the impact of combining improved monitoring with non-synthetic treatments to unlock the future of slug control.

CHAP's Dr. Jenna Ross OBE led the project. She said: "Traditionally, methods for slug control have relied on actives such as metaldehyde or ferric phosphate. However, concerns relating to the over-use of metaldehyde and its impact on non-target organisms have resulted in its subsequent ban in the UK."

"This meant that it was time to look beyond the existing crop protection toolbox to more innovative solutions such as nematode-based bio-molluscicides, which is a particular passion area for me as a nematologist. But despite their effectiveness, bio-molluscicides are expensive, so we needed to find a way to make them more cost-effective."

"SlugBot investigated that conundrum and answers, can we improve monitoring to know exactly where slugs are located in a field, and then spot apply biologicals to reduce the amount required and therefore cost? Excitingly, we've shown that it soon could be reality."

The project was delivered in three phases, combining a range of expertise across malacology (molluscs), nematology, biological control, crop protection, machine learning, artificial intelligence (AI), multispectral imaging, and spraying technology.

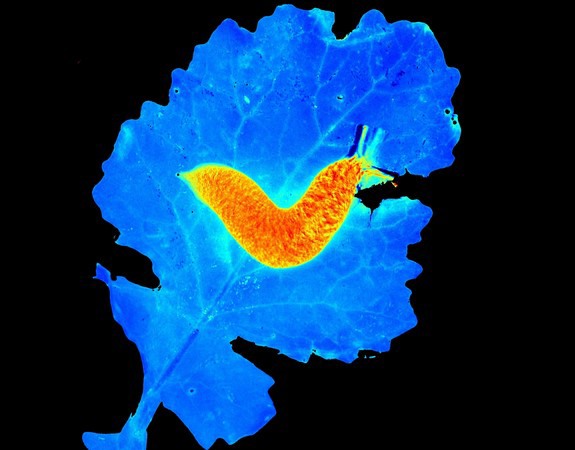

Stage one included slug collection, imaging at the CHAP and Rothamsted Research Digital Phenotyping Lab, and the development of an AI model. More than 1600 slugs were collected during this phase but focused on two main species – the grey field slug and the Spanish slug. Image data was collected across a wide range of environments and scenarios to help feed and train the AI model.

For stage two, slug mapping capabilities were trialed in glasshouse and field conditions, using Small Robot Company's 'Tom' robot. This stage also included on-farm testing at AV and N Lee, testing Tom's ability to take images, upload them for processing and identification, to then trigger the spray application.

Stage three

Finally, stage three focussed on developing the precision spraying capabilities of the robot and trialing its use with a biological control agent. A 1-meter boom was developed, adapted from a conventional spraying system, with the final prototype capable of spraying 20x20cm.

Andy Hall, Product Manager for Robotics, Small Robot Company, said: "The Slugbot project has enabled Small Robot Company to develop an AI that can detect and map slugs in a field using our monitoring Tom robot and also an on-robot precision detect and spray system, which can be used to spray slugs in real-time."

"The collaboration between Small Robot Company and CHAP has built many relationships which will benefit both organizations in the future."

James Lee of AV and N Lee said: "Experiencing technology in the field to examine new methods of slug control was truly fascinating. Bringing different skills and knowledge together through the project partners to work towards a solution to move agriculture forwards was the real positive for me."

Although the project has recently concluded, the work has proven the potential of autonomous monitoring and precision application within broadacre arable crops. Now established, the platform could be adapted to include new data sets to target a wide range of weeds, pests, and diseases.

Dr. Ross added: "What began as an idea from my Nuffield Farming travels soon snowballed into what has become a ground-breaking research project. Failure to control slugs has a huge impact on the agricultural and horticultural industry in both the UK and overseas, but now we have a solution that could have a significant impact with regards to net zero and sustainability."

"SlugBot has really pushed the boundaries for what is possible."

For more information: CHAP

CHAP

enquiries@chap-solutions.co.uk

www.chap-solutions.co.uk