"At TTA, we already proudly provide indoor farms with the latest technologies in handling and selecting plants. But, to succeed in our mission to supply customers with an automated solution for their entire production process, we are developing new innovative automation equipment. That's why it's time to get acquainted with the bHarvest: TTA's automatic solution for harvesting indoor-grown crops,' says Chris van de Vianen, Marketing manager at TTA.

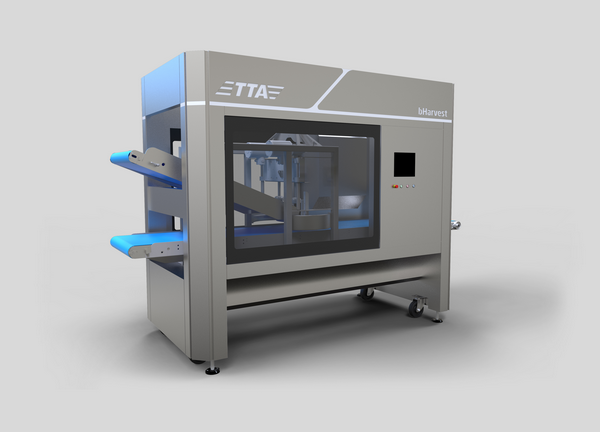

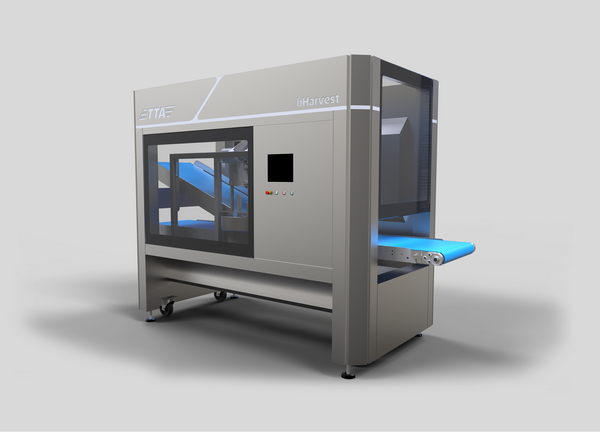

bHarvest

bHarvest(ed): it's all in the name. The machine comprises multiple in-and-out conveyors, including a cutting unit for processing products. The device is easily accessible from the side and equipped with a recipe-driven operation enabling easy operation and adjustments.

A change system for replacing harvesting knives contributes to a clean operation. Besides that, bHarvest can be combined with a check or belt weighing unit to ease the entire product processing.

According to Peter Rietveld, Business Development Director of TTA's parent company Eurogroep, this is the tip of the iceberg. "TTA is rapidly growing and forging ahead, luckily. We're constantly developing new machines to complement our automation solutions for indoor farming. We aim to create the most efficient indoor farm by combining your ideal environment with our high-tech automation equipment for the entire production process. Meaning, from sowing to planting/selecting, harvesting and all logistic movements in between."

For more information:

For more information:

Peter Rietveld, Business development

+31 (0)184 69 1105

[email protected]

TTA EU

www.tta.eu