Exeter Engineering, an American manufacturer of electronic sorting, washing, receiving, and related machinery for the fresh produce industry, has installed an upgraded version of its proprietary ID Technology system that uses artificial intelligence (AI) to automatically grade and sort bell peppers.

The system uses an integrated suite of cameras, lighting, and software to size and grade bell peppers for color, size, weight and even shape defects, all using AI to implement operator-set grading choices. It transmits live images of every bell pepper passing through the sorter, across all lanes, to operators, allowing them to adjust on the fly or see the effects of adjustments they are considering.

"AI-powered grading gives packers some gains in speed and accuracy, especially compared to older systems," said Matt Lonczynski, sales engineer at Exeter Engineering. "We are already seeing accuracy rates of 90 percent."

The bell pepper capability is one part of the upgrades made to ID Technology in its second major release: version 2.0. Hardware improvements in version 2.0 included a new camera hood and upgraded lighting. "The new lighting was crucial for getting imagery of sufficient quality to successfully size and grade bell peppers," said Boomer Batchman, president of Exeter Engineering. "With better imagery in both visible and infrared light spectrums, the AI gives more accurate results."

Oculus 1300 compact 3-drop sorter and an example of ID Technology 2.0 for potatoes.

Oculus 1300 compact 3-drop sorter and an example of ID Technology 2.0 for potatoes.

Potatoes

The ID Technology system has been working on potatoes for over a year, with accuracy rates of 95 percent on some customers' packing lines. The new version 2.0 hardware, combined with a software upgrade, now allows potato packers the option to use the AI to differentiate between three or more grades. They can also use the new "severity classification" feature, which allows operators to adjust for the severity of a variety of defects to move products from one category to another.

"With 'Severity classification,' ID Technology is coming out with another unique feature," said Lonczynski. "It allows the sort of granular control that used to come only after an operator had years of experience. Now it's automatic."

Exeter Engineering is currently testing a new version of ID Technology's software suite that will add the ability to sort sweet potatoes, and it hopes to have that capability by Fall 2022.

"By upgrading to an AI-powered system, packing houses can save both time and money," said Batchman. "ID Technology provides reliability and consistency quicker and more efficiently than older systems, which relied more on the skill and experience of the operator. Our potato clients are looking at returns on their investment in a year, a year-and-a-half. We think there will be a similar result for bell peppers, cucumbers, and other produce types we have in the pipeline."

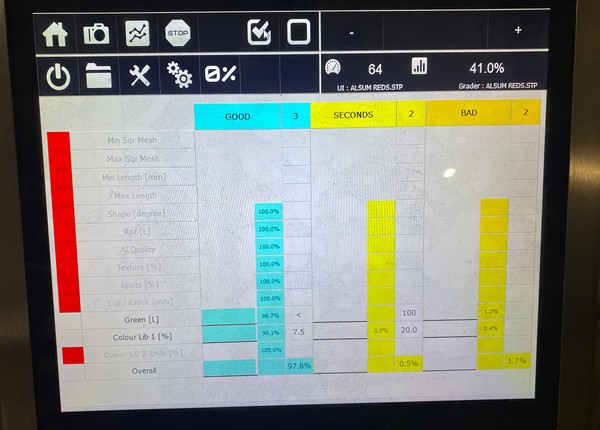

This screen shows the accuracy of various defects. It's just one screen of the ID Technology 2.0 control interface.

This screen shows the accuracy of various defects. It's just one screen of the ID Technology 2.0 control interface.

For more information:

For more information:

Boomer Batchman

Exeter Engineering

Tel: +1 (559) 592-3161

bbatchman@exetereng.com

Matt Lonczynski

Exeter Engineering

Tel: +1 (559) 592-3161

mlonczynski@exetereng.com

https://www.exeterengineering.com/