Strawberry is a crop of high economic value and is widely grown all over the world. For strawberries in greenhouses during winter, due to the weak natural light intensity and short daytime time, as well as other factors that influence light transmission, the lack of sunlight in and the imbalance of light quality are affecting plant development. This can cause problems such as the unhealthy main stem, high incidence of deformed fruit, decreased yield and overall poor quality. In order to improve the yield and quality of strawberries, artificial light supplementation is usually required.

With its strong photon output, the LED artificial lights for strawberries are located in the wavelength range where plants are more sensitive to different light sources. As such it can greatly promote the photosynthesis of green plants, thereby improving the quality and production of fruits.

Ledestar has conducted a spectrum experiment that has shown that red light is most beneficial to the growth of strawberry plants.

Some data shows that the content of soluble solid matter does not change much after the strawberry is supplemented with artificial light. Meanwhile the sugar content, total acid and vitamin C levels are significantly improved: sugar content is increased by 19.3%, and the vitamin C content increased by 21.8%.

Red light can significantly improve the level of photosynthetic pigments in plant leaves, the efficiency of the PSII reaction center and the sugar content, and promote the accumulation of fruit sugar, soluble protein and anthocyanin.

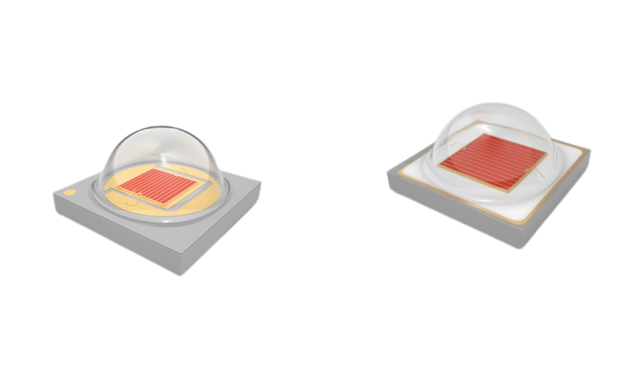

The latest LED 3535 660nmL9 product line launched by Ledestar is committed to providing higher-performance for major plant cultivation and Led grow light manufacturers. The line is providing higher PPE and PPF for growing vegetables and fruits such as strawberries and tomatoes.

The overall parameter efficiency of L9 has been increased by 1.5%, and the efficiency value of @700MA PPE is as high as 4.2umol/J. In addition, a new gold plating process is added to improve the anti-sulfur performance by 3%. If the product is placed in a sulfur-containing environment of Ta=25℃±5℃, 1g/1000ml and the current is continuously lit for 4000H through 350MA, the PPE efficiency maintenance rate is 97%.

"Every improvement is a technical breakthrough. In this increasingly competitive market we can only go further by continuously improving our R&D capabilities and providing high-quality products," concludes Tony from Ledestar.

For more information:

For more information:

Tony Chen

Ledestar

www.ledestar.com

Email: info@ledestar.com

WhatsApp : +8613527991330