Temperatures of over 30 degrees Celsius in the summer are no deterrent for Austrian grower Frutura. It can get pretty hot in the Styrian region. High radiation levels, which quickly rise above 3,000 joules in the second half of spring, are also the rule rather than the exception. "We have a lot of light here early in the year," says grower Marcel Rohrborn. Two and a half years ago, he was one of the first users of the model-based crop planning platform ProJoules, whose digital portal was launched more broadly earlier this year.

Marcel behind a screen with ProJoules on it in his office at Frutura

From tomatoes to peppers

In Bad Blumau, Marcel is responsible for the cultivation of five hectares of pointed peppers. Head growers Martin Gunda and Jan Ravensbergen grow tomatoes and organic vegetables in the other greenhouses. The range of the Austrian greenhouse vegetable producer has expanded considerably in recent years, as has the cultivated area, which now totals 26 hectares. Organic radishes have been added, as well as the organic cultivation of aubergines. Besides conventional tomatoes, Frutura also has several organic tomato varieties in its range.

For the past three and a half years, Marcel has experienced the growth of the company at close quarters. He came from an Austrian greenhouse horticulturalist and had previously worked in Germany, Hungary, and Sicily. "I didn't have a wife and child then," he laughs. The common thread in all those years was the tomato. It wasn't until Marcel was in Austria before he started working for Frutura that he learned about growing peppers.

It was at the Austrian grower's that Marcel met cultivation advisor Wim van Wingerden. "This isn't for me, I thought at first, when I started growing peppers," the head grower remembers. "The cultivation of pepper is completely different from tomatoes. The whole cultivation process was unknown to me. I find it more difficult." Wim used to be a pepper grower himself. It was in Austria that Marcel first started working with him. Marcel also met Wim again at Frutura. "When I started at Frutura, Wim was there from the beginning."

Marcel is responsible for five hectares of pointed pepper

Insights

A year after Marcel started at Frutura, COVID broke out. "Wim is here every three weeks, but due to COVID and personal circumstances, that didn't work out for a while. Then he asked me if I wanted to work with ProJoules in Excel via Dropbox. I was ready for it. I believed in it."

Working with ProJoules made it easier for the grower and the cultivation advisor to communicate remotely about the crop. "Thanks to the data I shared via Dropbox, Wim was able to follow the development of the crop much better."

Both men have already shared photos and observations digitally. Through ProJoules, the exchange of data has also been facilitated. Entering data is the basis for using ProJoules. Marcel says he spends about five minutes on this task each week. "That is the time it takes me to register. That's not bad at all and takes me a lot less time than it used to when we still worked with our own spreadsheets here. Besides, that was nowhere near the scale of what we do today."

Simplifying the communication of cultivation was immediately one of the benefits, but not the only one. "Since I have been working with ProJoules, I work more efficiently, and my data is clearer," says Marcel. "In return, I receive a lot of insights." Another advantage is that the accumulated knowledge is not lost if one of them leaves unexpectedly. This is practical, also with a view to possible new colleagues. "They also get a good insight into the cultivation. In addition, ProJoules is also a tool for communication with management and trade."

Using the platform for crop planning based on models also provides information on expected production. "This allows us to plan our volume better. A colleague recently said enthusiastically that there is hardly any difference between what the model says and what happens in practice. That is important for us because we want to get the product on the shelves quickly and freshly, and the people further down the chain appreciate that."

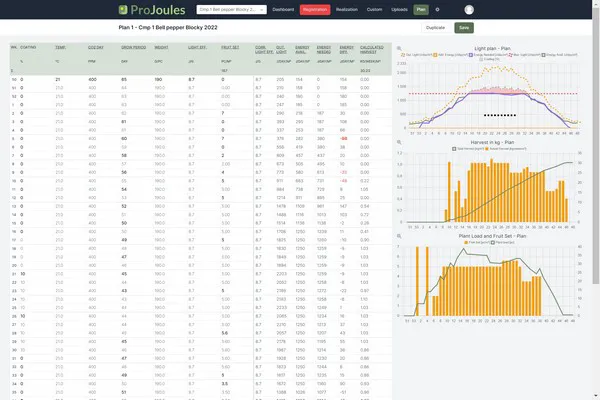

Example of random cultivation plan for peppers. Click here to enlarge

Radiation

The name ProJoules highlights that the model revolves around light, or rather joules; the total amount of light in the greenhouse at the plant level. Marcel, therefore, enters data on the incidence of light into ProJoules, alongside other climate data and data on fruit weight. He has been using the ProJoules portal since December last year. This allows radiation values to be calculated at the plant level on the basis of external light. "Thanks to the program, I can now see whether I should keep to the number of fruit the plant has produced. Can the plant convert the amount of light into production? Or is there perhaps too much light? With ProJoules, I can see this much faster than before. So you can be proactive and, for example, close the screens or apply a coating."

In week 16, the first coating was applied to the greenhouse deck in Bad Blumau. "At that time, 10 buckets per hectare were used. In week 22, another 10 buckets were used. There is a lot of light here in Styria. We are used to that now. With ProJoules, we can see exactly how much light is needed for the plants, and we can also make the right decisions to limit the radiation, for example, to keep greenhouse temperatures down in summer."

In week 16, the first layer of coating was applied

Lighting

Things are different in winter. That's when light is welcome. The use of geothermal energy provides heat for heating the greenhouses. "My colleague Martin is responsible for tomato cultivation under lighting. He has also started to use ProJoules. I am now supporting him in that. Martin is currently getting to know ProJoules. The program is easy to use."

Frutura uses ProJoules on 2 hectares of lit cherry tomato cultivation. "Especially in the lit tomato crop, I expect that thanks to the findings of ProJoules, there will be opportunities to save energy costs. Perhaps you can sometimes work with fewer hours of exposure," the head grower thinks aloud.

ProJoules is now also being tested in a department with organic aubergines. "Quite a challenge," says Marcel, "because we still have a lot to learn about the way the aubergine plant grows, such as how long it takes for the fruit to ripen and what role the number of joules plays in that. The model will soon give us insight into this. I am convinced of that."

The developers of the ProJoules portal are also constantly coming up with new insights, thanks to the growers. Marcel: "It is already working well, but of course, there are always small improvement points. For example, we still need to calculate the temperature difference between day and night. After I mentioned this, Wim picked up on it immediately. By working with ProJoules, we also benefit from future updates."

Orange pointed peppers in the greenhouse at Frutura

For more information:

ProJoules

[email protected]

www.projoules.com

Frutura

www.frutura.com