Can the sector do without the audience of around a hundred horticulturalists? That question was asked during day 1 of the RoboCrops event, organised in Netherlands last week. The tone was set for a day full of robot developments. Twelve companies were invited to pitch their innovations. Here's twelve horticultural robotic solutions to keep an eye out for.

From drones to data with AgriData Innovations

William Simmonds of AgriData Innovations kicked off the round of pitches. He explained that the company has switched from drones to data in recent years and is now staying away from the mechanization issue as much as possible. To do so, ADI relies on existing techniques, such as drones or a spray boom in the greenhouse.

CTO Lucien Fesselet with AgriData Innovations

CTO Lucien Fesselet with AgriData Innovations

"ADI provides an integrated, data-driven solution that enables growers to monitor their crop at scale. We collect data, analyse and process information and deliver actionable insights to growers and cultivation managers."

AI controlled control with Crop Controller

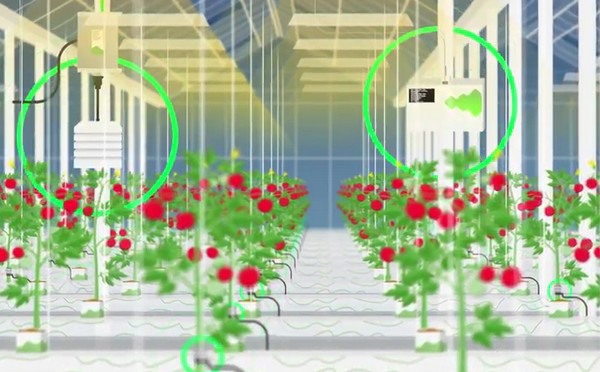

Ronald Hoek of Blue Radix is now active in eight countries worldwide with a technique, Crop Controller, based on artificial intelligence. Blue Radix combines the input of crop measurements with smart algorithms, which can be used to translate the data into prediction models and the necessary changes to autonomous climate control

There, the Crop Controller service helps growers implement their unique cropping strategies and scale up operations with the help of algorithms.

Cherry tomato on the cake

Edwin Vanlaerhoven of Certhon. Edwin talked about the Certhon Harvest Robot. Certhon is currently working with Japan's Denso to further develop the robot, which will be used to conduct new greenhouse trials in the fall of 2022.

The market launch of the robot is expected in 2023. The robot can work safely together with humans and should take on 40-80% of the harvest of cherry tomatoes.

At the GreenTech Amsterdam, Certhon will also launch a complete robotic concept for snack tomatoes. To be continued...

Drones flying back and forth

Frans-Peter Dechering of Corvus Drones did not give a demonstration with the drone ("boring, because it only flies back and forth") but put the focus on data collection. Since February 2022, the drone has been flying in the greenhouse at plant grower Gitzels. Corvus Drones aims to have 20 customers this year, 100 next year and a deadline has already been set for 1000 customers as well.

Data, data and analyzing

Andreas Hofland of HortiKey talked about the Plantalyzer. The Plantalyzer collects data for the grower in the greenhouse. This data can be used to predict the harvest. In response to a question from the audience as to whether HortiKey is already looking further afield, Andreas explained that it is also working on collecting data on pests and diseases in the greenhouse.

Honesty and tomatoes

Kaede Morita of inaho Europe talked about the tomato harvesting robot that the company has on the market. Kaede won praise by also showing that the robot sometimes misses when harvesting tomatoes. Since April, the robot, which could be seen at Tomatoworld last year, has been operating in the greenhouse of a Dutch grower.

Always data inundated

Ton van Dijk of LetsGrow.com first took the audience back in time to when he was still a grower some twenty years ago.

Ton showed that much has changed since then, but then again it has not. The grower is still inundated with data. LetsGrow.com wants to help growers understand data. Data visualization is important for this.

"LetsGrow.com offers growers, crop advisors and suppliers around the world solutions by providing insight into their cultivation data and current situation in the greenhouse. The available data from the greenhouse is analyzed and combined with plant physiological models, knowledge and experiences in the field", he explained.

For example last year, LetsGrow.com joined forces with SenseNL, producer of the wireless substrate-independent CARA MET sensor. Earlier LetsGrow.com already integrated tools like the Google Glass into their smart dashboard and developed visual data support; the LetsGrow Livestream

PATS-X or PATS-C?

Bram Tijmons of PATS Indoor Drone Innovations talked about PATS-C, a system that detects real-time flying pests, such as moths, in the greenhouse, and PATS-X, which detects an insect infestation from day 1. PATS uses vision and AI to detect insect pests and then fights them with small drones: Bram also showed action footage, where the drone is able to pick moths out of the air even in a high-wire growing tomato.

Last year PATS received an investment. The funding will be used to put the first commercial module of the technology on the market on a large scale.

Stepping stone

Thomas Hoeterickx of Priva Kompano / Octinion revealed that at GreenTech both companies are coming together with a new name, after they already combined their robot activities last year.

Octinion sees in the Lumion-UV-C robot a way to introduce the grower to an autonomous driving system in the greenhouse. A stepping stone to more robots in the future. The company offers the mobility solution on which other robot applications can be placed to other parties.

New best fellow

Jasper van der Auweraert of Sobolt/Plantfellow. Plantfellow is the brand for horticulture with which the Rotterdam-based AI company goes public. Plantfellow offers ScoutCam, for digital pest scouting, and AutoPheno, a phenotyping tool that should take over 90% of the grower's phenotyping work at 20% of the cost, Jasper indicated.

ScoutCam is a digital scouting solution to measure pest pressure. "In this way, population growth of pests in the greenhouse can be noticed more quickly and economic damage can be prevented. Monitor the pest development in the app and take targeted action", he said. "ScoutCam automatically counts and analyzes catch and signal plates. ScoutCam's cameras are more accurate than the human eye. You set the standards for an alert on the app and ScoutCam does the rest. By using artificial intelligence and the user-friendly dashboard, you as a grower have faster and better insight and overview."

Turning another leaf

Harry Schonewille of VDL ETG Projects told about the VDL CropTeq leaf cutting robot. Harry explained that the goal is to commercially market the robot for use in cucumber cultivation by the end of 2022. After a question from day chairman Peter Jens, he also indicated that VDL, a very large company that operates not only in horticulture, does not hesitate to buy or invest in companies to achieve its goals.

Post harvest quality

Harm van Adrichem of Gearbox Innovations briefly introduced the audience to the four product lines the company offers. The common denominator: quality inspection.

Using artificial intelligence and the latest vision technologies, GearStation for example manages the inline quality control and grading of fruit, vegetables and flowers in punnets, as single units or in crates.

A similar setup with different purpose can be found in the GearStation Crate Inspector; accurate and consistent quality check of empty reusable transport items for organic rest materials, stickers, damage, dirt, etc.

.JPG?preset=ContentFullSmall)