At the end of the 1980s, the AutoCad drawing program was introduced in horticulture for making installation drawings. This was a big step forward in the quality and detailing of the drawings, says John Vollebregt, COO of Tebarex. In 2021, a new step was taken, and Tebarex switched to REVIT 3D installation drawings.

Drawings based on good explanations

The AutoCad drawings quickly became a household name in horticulture and the demand to draw all greenhouse installations fully grew. John: "In my career of more than thirty years in the horticultural sector, I can state that the drawings have always played a very important role in the proper implementation of the projects. These drawings were and still are the tools for supervisors abroad to be able to explain properly to the local assembly teams what needs to be installed."

3D

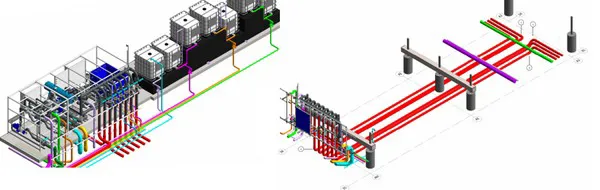

The transition from AutoCad 2D to drawing the projects in REVIT 3D this year means that the entire ground plan, consisting of all pipes and ground cables, is designed and detailed in the 3D environment. Conflicts in intersections are easily made visible and solutions are worked out in a 3D environment. "By putting more time into the work preparation and the creation of the 3D drawings, the execution will go a lot smoother, allowing work in the field to be done faster and more efficiently," expects John.

For a 22 hectare project (Ely-Fenland UK) commissioned by Bom Group, a single 'master drawing' is being created, which is divided into sectors, John explains. "Then, only overview drawings are printed on paper and all details and working drawings can be viewed via a tablet or smartphone. This saves a lot of paper compared to the previous drawing method."

Details

By clicking on a sector in the master plan, a number of details are displayed on the left. By clicking on a link, the corresponding detail is shown and one can rotate it in all positions via 3D viewer (Dalux). "With this, the supervisor can call up the specific details at any location in the greenhouse and instruct and check local technicians. When the supervisor is back in their hotel, the drawings are synchronized, so that the next morning they go out with the most recent drawing. By making notes in these details on site and marking GPS positions, as-built drawings can easily be produced after installation work is complete."

Tebarex ensures that a project, simple or complex, is drawn out in 3D at a professional level, John concludes. "That way, the installer has fewer worries during execution. The work is carried out as designed and the installation can operate smoothly for years."

Need more explanation? John is happy to provide it.

For more information:

John Vollebregt

Tebarex BV

Jogchem van der Houtweg 4

2678 AG De Lier

T +31 (0) 85 483 2170

john.vollebregt@tebarex.com

info@tebarex.com

www.tebarex.com