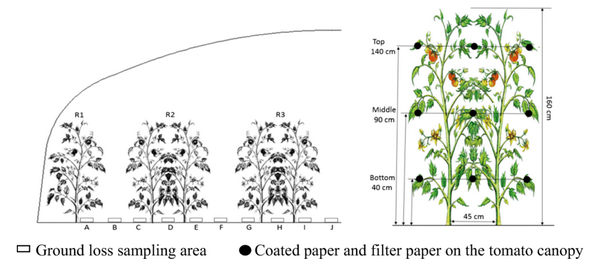

A field study was conducted in plastic tunnels of tomato crops to compare the spraying performance of KMS with the commonly used electric knapsack sprayer (EKS), thermal fogger sprayer (TFS) and spray gun (SG).

The environmental conditions of facility vegetables are characterized by high temperature and humidity, promoting a high incidence of pests and diseases.

To change the backward status of plant protection machinery in greenhouses, a new kind of knapsack mist sprayer (KMS) was designed. The sprayer can reach a maximum wind speed of 12 m/s near the air-flow outlet, the spraying range is 9 m, and the droplet volume diameter is 45 μm.

Study results

The results showed that the droplet distributions of KMS and EKS were similar; the coverage and deposition of spraying liquid decreased with increasing spray distance, while the deposition of KMS on each ridge was more uniform than that of EKS. Compared with EKS, TFS and SG, the KMS can effectively reduce ground loss and increase the utilization of the spraying liquid.

The average ground loss and utilization rate of the spraying liquid of KMS were 10.58% and 67.8%, respectively. KMS has a good droplet penetration effect, which promotes uniform deposition in the middle and bottom parts of the tomato canopy.

Overall, with advantages of high operating efficiency, low labor intensity, low spray volume, high utilization rate of liquid and uniform deposition, KMS can be used for pest and disease management in greenhouses.

Click here to access the complete study.