For years, it was mainly either 'standard' glass Venlo greenhouses or 'standard' foil greenhouses that were erected for growers at the most diverse locations internationally.

In the meantime, the greenhouse has become a tailor-made suit and you increasingly come across specifically designed greenhouses, for which various greenhouse builders have developed their own concepts.

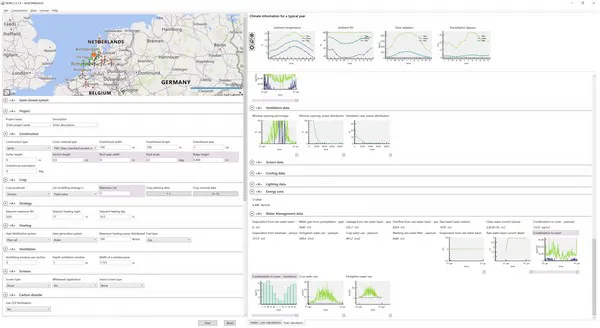

To give greenhouse builders the opportunity to simulate how the greenhouse will function prior to construction, TNO designed the greenhouse modelling programme SIOM on behalf of the Hortivation foundation. In week 28 a new version will be delivered, with the option to do a digital simulation for semi-closed greenhouses as well.

With the programme, companies that have obtained a licence from the Hortivation foundation can design an optimum greenhouse for their location. Egon: "This gives them a knowledge head start and is an important trigger to get in touch with potential clients."

Another new development is the development of a GeoKas database. Publicly available data about climate, energy and other important information that is important for the design of a greenhouse complex can be made available in both SIOM and the CASTA greenhouse design programme at the push of a button. "This allows the design to take even more account of local factors that can optimise the design both technically and economically."

Click here to enlarge an insight into a water cycle in SIOM

Preventing mistakes

Egon Janssen, the greenhouse horticulture man within TNO, explains that SIOM has been in development for seven years. The tool is used by thirteen greenhouse builders. Simulation software is not new. Wageningen University & Research also has a simulation model: Kaspro. "That system is often used by researchers", Egon says. "For 'standard' greenhouses, greenhouse builders use SIOM. This system is practical and helps them to design and set up a greenhouse for cultivation anywhere in the world. If things get complicated, we can help out, and if it really gets too complicated, then there is always Kaspro and the specialists from WUR."

By simulating, the designer avoids mistakes. "The software makes it possible to digitally run a crop for a whole year, so that you can see whether all the systems have been calculated correctly to meet the grower's requirements and the climate influences at that location.

Software is also added that simulates the entire water cycle in the greenhouse simultaneously with the new update of SIOM. "The system tells us straight away what the water balance is like and whether, for example, additional water basins or osmosis installations are needed."

Better comparison

The inclusion of semi-closed greenhouses in TNO's greenhouse modelling programme was done at the request of the SIOM steering group. Five of the 13 greenhouse builders affiliated to the Hortivation Foundation are members of this group, all of which are SIOM users. "They determine what the development agenda will be and the semi-closed greenhouse was high on the agenda, given the growth in that market."

Until now, of course, simulations and calculations had already been carried out by a number of greenhouse builders themselves. "However, they all have their own system for this with their own calculation approach. That meant that when an investor requested quotations, there were sometimes different answers to the same question. In itself this is not a problem, because this is also possible with the update of SIOM, but at least the calculation method is now the same. This standardisation makes it possible to compare better, while of course everyone can still follow their own strategy."

All data together

More and more data is involved in designing a greenhouse. To ensure that greenhouse builders do not have to digitally scrape together information from all over the world, TNO is working on a database in the GeoKas database project in which public data about such matters as climate and energy can be retrieved at the touch of a button. This project is being carried out by TNO on behalf of the Hortivation foundation.

Egon explains how it works. "Simply typing in the GPS coordinates of a location will soon suffice to obtain information on, for example, historic precipitation data at that location, but also on the presence of industry. Greenhouse farmers have to take this into account as well, because an industrial complex nearby can provide growers with valuable residual heat and CO2."

It is not difficult to find out whether these possibilities exist. But the idea is that the system will also give direct access to the emission data of a complex like this, so that not only the greenhouse builder, but also the grower or investor himself, can see whether the source can actually be of value.

Dream of the future

The number of available public datasets is still growing rapidly worldwide. That makes it a tough job to keep everything up to date. "Not all information is available in every country, but meteorological data, for example, is easily accessible worldwide and satellite data is also plentiful." A potential additional source of information is the metadata collected by Google Maps, among others. Think of descriptions of photos of locations. "In our vision of the future, the greenhouse builder will be presented with all the relevant information about a construction site and about how the greenhouse can fit into the region".

The latter is also precisely the role of the Hortivation foundation, adds Lindy van der Drift on behalf of AVAG/Hortivation. "Cooperation in the pre-competitive phase. The entire sector needs the same information. So why not unlock this data together?"

For more information:

Egon Janssen

TNO

egon.janssen@tno.nl

+31 (0)6 53 46 76 64

www.tno.nl

Stichting Hortivation

info@hortivation.nl

www.hortivation.nl