There is a lot of movement in the greenhouse light market at the moment. Over the coming two months, greenhouse vegetable growers in Northwest Europe will certainly have to make decisions. And also in floriculture growers are faced with choices. Do they want to use (more) artificial light? And if so, with which fixtures above the crop? With what spectrum? With which installation? And how to deal with the energy part?

Looije Agro Technics supports growers as an independent consultancy bureau with these issues and, in a series of four articles, examines these questions from different angles and strategies and more. Today part 1: the choice between HPS, LED or a combination.

The concept of lighting viewed uncoloured

Where the classic HPS fixtures have already proven themselves in production, Looije Agro Technics believes that since the arrival of large production series of LED modules, the concept of lighting needs to be rethought.

"We have a realistic life expectancy of the bulb for the HPS fixture and we know the light output independent of manufacturer. LED fixtures, on the other hand, are continuously developing. Fixtures increase in efficiency every year suppliers come and go. Lighting in a horticultural greenhouse, an environment with extreme conditions, does not appear to be self-evident for everyone. However, there is sufficient knowledge and experience to make the right choices for specific crops. The step to a hybrid or full-LED lighting installation is becoming smaller and smaller. "

A combination of HPS with LED lighting

Spectrum choice

Where the HPS fixture tries to approximate the PAR spectrum including far red as closely as possible in its entirety, the excess of red and blue light is characteristic of the LED fixture. The emission of specific wavelengths is characteristic of LED fixtures. Positive for electrical efficiency, possibly disadvantageous for production. Especially when crucial wavelengths are missing, according to the Looije specialists. "In our opinion, good artificial light advice starts with determining the right spectrum."

In addition to the spectrum, there are major differences in the output of LED fixtures. The choice to achieve the desired output requires a multidisciplinary approach. "We look at the availability of energy with associated (variable) costs, the specific structure of the greenhouse and desired position of the fixtures, the budget, the desired cultivation output in the form of production, uniformity of lighting and in the event of conversion into an existing installation, also for the desired reuse of existing components. "

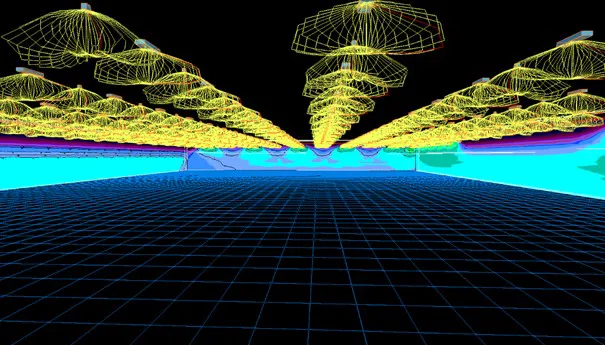

3D lighting plan

Based on spectrum and output, the Looije specialists select different fixtures together with the grower, which are placed next to each other in a (3D) lighting plan. "We see a lot of ignorance and fudging with figures in the market. By measuring fixtures ourselves, we are able to realize a tailor-made lighting plan with different fixtures. The combination of light requirement, greenhouse, cultivation and grower make every situation unique. We have no hidden parameters or different modelling between the scenarios. The different scenarios with full LED, HPS or hybrid options are made with different fixtures for the grower's specific situation. We are independent and can work with any supplier. "

A tailor-made 3D lighting plan with which different fixtures are compared.

Complete comparison

In addition to modelling, the Looije specialists make a technical and financial comparison of not only the fixtures, but of the entire installation, including the production phase. "In this way we can provide insight into the payback time of various installations. We take care of both technical and commercial negotiations. Our construction supervisors, if necessary, are also present prior to and during the installation to ensure that the concept developed on paper is efficiently and correctly converted to the practical situation. All this concluded by one or more frequent repeat measurements in order to be able to monitor the output (differences) and to take timely action."

Looije Agro Technics wants to bridge the gap between theory and practice. "By means of our own knowledge and experiences in practice, the field and laboratory, we are able to translate the grower's lighting needs into untainted advice with a brand-independent view. Our X factors are objectivity and independence."

For more information:

Looije Agro Technics

[email protected]

www.lat.nl