The fresh produce market has rapidly developed in the last few years, but fresh produce suppliers face significant risks related to cold supply chains and storage management. One of the most important elements of cold supply chain management is the ability to accurately monitor temperature and location. Fresh-key, a Chinese developer and producer of thermometers for the cold supply chain industry, recently collaborated with DiMuto, a Singaporean tech company, to implement a system of advanced market monitoring.

Strengthening cooperation based on segmented supply chains and Internet of Things technology

According to Gary Loh, the founder and CEO of DiMuto, "as a tech company in the cold supply chain industry, we pay careful attention to the direction of developments in cold supply chain technology. One of the main trends in cold supply chain management will be the systematic integration of cold supply chain segments and Internet of Things technology. The ability to monitor data in the cold supply chain is a vital element of this development. We chose to work together with Fresh-key because we agree on the importance of these two aspects."

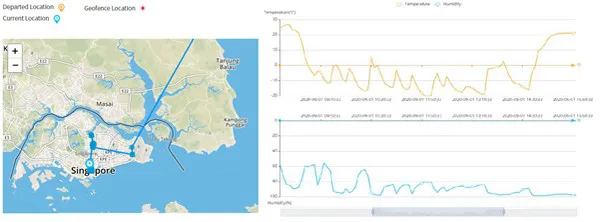

Fresh-key and DiMuto carried out a test of Fresh-key's latest 4G-cat 1 real time monitoring solution. During this test, the data logger was placed in shipping containers full of ice cream for a period of 20 days. The data logger recorded the temperature inside the shipping containers at every stage of the supply chain, and also noted how long the shipping containers spent in each location. The data monitors also tracked whether temperature values remained within acceptable margins. When the temperature was too high/too low, then the data monitors would transmit a warning.

The location data helped to visualize the efficiency of the cold supply chain, and locate areas where the shipping containers remained stationary for too long. Both parties were extremely satisfied with the test results. They are now discussing the next step in their cooperation. This data monitoring device will be used in the supply chain management of a wide variety of fresh fruits and vegetables.

Efficient and widely applicable 4G technology becomes a trend

"Many developed countries have already replaced their 2G devices with 4G technology. In the long term, 4G technology is more widely applicable, because 4G technology covers a wider area. That is why this technology is becoming a trend in many countries across the globe. For example, one of our clients is a New Zealand fruit supplier.

"They purchased our 2G, real-time thermometers, but the fruit they exported to Taiwan had product quality problems, because Taiwan had already discontinued 2G services. The actual data only covered the brief journey from the processing factory to the New Zealand harbor from where the fruit was transported to Taiwan. When the Taiwanese importer tried to trace the source of the product quality problem, they could only conclude that this occurred during transport. They had no way to see what happened to the containers in the vicinity of Taiwan, but could only rely on our data for the first stage of the supply chain."

Another advantage of 4G Cat-1 technology is low-power consumption with high data rate, which keeps the data efficiency during long-time monitoring application. This technology would be more and more used in IOT solutions in the future, and very proper to the long-distance transport of fresh produce.

The public is paying more attention to fresh produce news since the outbreak of Covid-19

The ongoing Covid-19 pandemic has led to significant changes in the fresh produce industry. According to Tina, "our order volume only began to recover after the Covid-19 outbreak was largely brought under control in China in the middle of April. This is, on the one hand, because some of our regular clients resumed operations, and on the other hand because consumption patterns changed during the pandemic. People now buy less in the markets and order more online. Furthermore, they have higher requirements for product quality and food safety. E-commerce platforms generally use cold supply chains for their products. In order to better monitor and control the product quality of their products during the journey or in storage, many platforms have begun to use thermometers during transport."

"Shanghai recently hosted the Global Cold Supply Chain Summit. Reports from this summit show that the Chinese agricultural industry faces technological changes and will require more digitized information. That is why agricultural technology companies are springing up left and right. Last August, Fresh-key was identified as National High-tech Enterprises in China. We believe we can take this opportunity to provide even more clients across China with even better products and services!" Said Tina.

For more information:

Tina Sun - CEO

Fresh-key (Shanghai) Technology Co., Ltd.

Tel.: +86 15000564488

E-mail: [email protected]

Website: www.fresh-key.com

Platform: www.fresh-iot.com