The prospect of big savings and generating a healthy income paired, with environmental legislation and net-zero emissions targets have spawned many biomass installations within the horticultural industry.

Many nurseries have proved that the RHI can provide a great additional income whilst allowing for substantially lower fuel supply costs. It’s no wonder organisations are rushing to reap the benefits of these renewable energy systems before the RHI supposedly comes to a close in March 2021. Taken from some recent figures provided by 4 UK based plant wholesalers, Bridge Biomass and Draper Heat have compiled some case studies outlining the considerably lower fuel costs and attractive returns that can still be received using a Biomass installation.

© Bridge Greenhouses

© Bridge Greenhouses

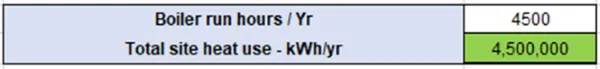

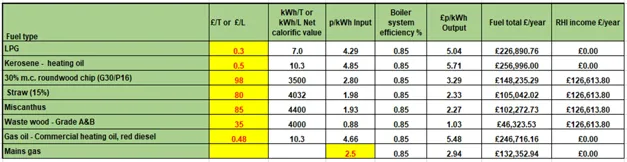

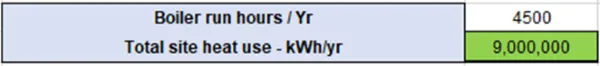

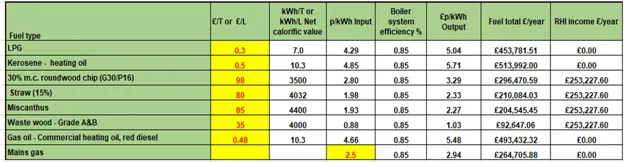

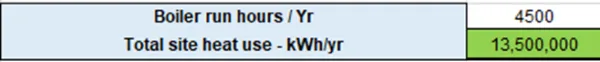

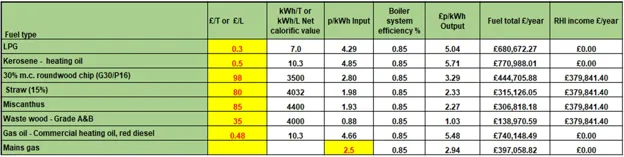

Covering a variety of boiler sizes, the following tables detail the specific cost of each fuel type, the system efficiencies as well as the inputs per kWh and the outputs achieved per £/kWh.

Glasshouse Case Study 1: 1MW MCPD Compliant Boiler System

Click here for a larger version.

Peak Savings (waste wood compared with gas oil) = £200,392.63

Plus, RHI payments = £327,006.43 total additional income p.a

The Renewable Heat Incentive has developed since its introduction in 2011 with the tariffs remaining appealing, especially for the larger systems in excess of 1000kW.

Before 2017 the RHI tariffs did not favour systems over 1000kW, however the revised tariffs now make them much more feasible for nurseries in the UK, with a lot of systems covering installation costs in 3-7 years and any remaining payments directly contributing to the business.

Glasshouse Case Study 2: 2MW MCPD Compliant Boiler System

Click here for a larger version.

Peak Savings (waste wood compared with gas oil) = £400,785.26

Plus, RHI payments = £654,012.86 total additional income p.a

As shown in the figures, the more fuel that is burned, the greater the output per £/kWh which results in a greater saving for the business. This is obviously relative to an increase in initial investment and the amount of space needed to house the system, however the payback in savings and RHI allows this initial cost to be paid off quickly, with the remaining income available to contribute towards business improvements.

Glasshouse Case Study 3: 3MW MCPD Compliant Boiler System

Click here for a larger version.

Peak Savings (waste wood compared with gas oil) = £601,177.9

Plus, RHI payments = £981,019.30 additional income p.a

Glasshouse Case Study 4: 6MW MCPD Compliant Boiler System

Click here for a larger version.

Peak Savings (waste wood compared with gas oil) = £1,202,355.79

Plus, RHI payments = £1,962,038.59 additional income p.a

Aside from lower fuel costs and RHI payments, Biomass installations provide stability among the fluctuation in fossil fuel prices, and the volatility of the major fossil fuel producers. With an abundance of renewable fuel suppliers, Biomass is seen as the more attractive proposition when considering a new or replacement heating system. Bridge Biomass design, engineer and build bespoke biomass heating systems for commercial organisations with a significant heat demand. Use the details below to book in a free consultation or request further information.

Bridge also specialise in the design and building of Greenhouse Structures and associated services along with Vertical Farming solutions.

For more information: Bridge Greenhouses

Bridge Greenhouses

Keynor Lane

Chichester

West Sussex PO20 7LL

01243 641789

info@bridgegreenhouses.co.uk

www.bridgegreenhouses.co.uk