Wouter Verkerke’s primary expertise is value creation of production systems in horticulture. Greenhouse horticulture contributes greatly to food security. Such systems are highly efficient in use of water, but are not yet fully circular and the energy costs are high. Wouter is now working closely with stakeholders to transform the current systems towards circularity and redesign systems so that all of the output streams can be used in other production systems.

Analysing the building blocks

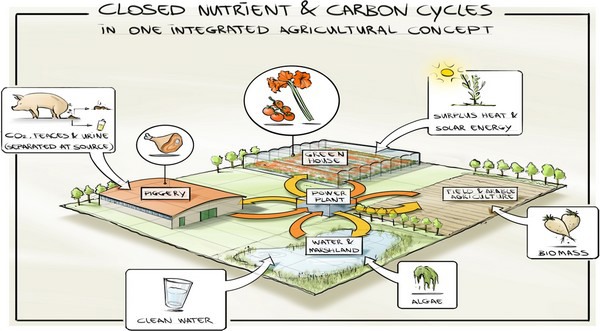

Circular Horticulture is defined in three words: Efficient, Clean and Connected. This implies issues such as less dependence on external natural resources, compulsory re-use of side streams, and that all side streams are produced to product specifications. To move towards a more circular horticulture, Wouter’s team is describing and analysing all present incoming and outgoing flows, calculating their impact on different environmental dimensions, and identifying the critical building blocks of circularity. This systematic analysis will form the basis of a redesign of production systems, including new business models, leading to a horticulture fit for the circular economy. The redesign will be in public-private partnerships with industry and government, to guarantee that the solutions will be used in practice and have a real impact on the circular economy.

Challenges and opportunities

Of course there are challenges that have to be overcome before we can embed horticulture in the circular society. In the Netherlands, we specialized in efficient linear production systems. For adding value, we use approaches such as currently are developed in The Greenhouse Pharmacy programme. If you then add circularity to the equation, life becomes more complex. On the other hand, efficient greenhouse production systems could potentially also solve problems with outgoing flows from other production systems.

Redesign of current systems

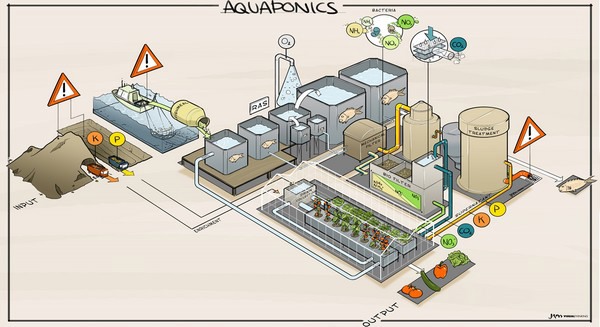

How can we prevent side streams like minerals, wastewater, plant residues etc. going to waste? A practical example: in the current tomato production systems, we end up with ‘waste’ products like tomato stems, potentially a source of fibres and polylactic acid. However, these stems are entwined around nylon support threads and it is difficult to separate the two. Such mixed green and fossil plastic streams have currently only limited market value. A redesign of the current production system is needed to produce clean outflowing streams that are of higher value because they can be used in other production processes.

Mined chemicals and fossil peat

On a larger, global scale, a major bottleneck to efficient agricultural production are the mined chemical fertilizers that are presently needed to ensure optimal plant growth, e.g. phosphates and potassium. Urban mining solutions will be necessary, but replacement of chemical fertilizers by organic fertilizers is also of upmost importance. In the future, the use of fossil peat in plant substrates will have to be abandoned. Peat as a substrate of eminent quality could at least partially be replaced by fibres from current organic flows through the application of new techniques, and this will create a positive impact on the current CO2 footprint. And the production systems need to be redesigned to cope with the new materials - We have a long journey ahead, both locally and globally!

Value creation in urban horticulture

Circularity will be the licence to operate in the future, but the products from your newly designed urban production system need to be sold here and now. Such systems therefore need to develop new stories as an answer to this problem. It is not much good producing low value crops like lettuce in an urban greenhouse just because you can, when indistinguishable but cheaper alternatives that are equally good are also abundantly available. The story of your production system and of your products should really appeal to the different types of values of your targeted end-users.

New context, new opportunities

Urban horticulture on the other hand could create new opportunities, but you should develop technical solutions to create the production system and the products that will act as a carrier of the stories you want to tell. Your products could be directly sold in an urban environment, and not necessarily in a retail setting. For instance, fresh fruits with a short shelf-life but with an excellent taste, are high-value delicacies that could be enjoyed as food to go. New combination with other food items could create new appealing products with a new, urban story. Your story on sustainability and circularity of your newly designed integrated urban production system has not only to match with the story of your products, but also match with local value systems. Values of embedded urban production systems could appeal to different values in different cultures.

About Wouter Verkerke Wouter Verkerke is business developer for The Greenhouse Pharmacy at Wageningen Plant Research. His programme develops new growing strategies and new business models for new crops, aimed at the production of valuable food ingredients, cosmeceuticals and plant-based medicine. He is presently developing a new programme on Circular Horticulture, connecting stakeholders from industry with Wageningen R&D. Previously he founded the Bleiswijk Flavour Lab for fruits and vegetables, the clearing house that provides a level playing field for companies that are working towards higher flavour levels in fruits and vegetables, such as seed companies, growers, and wholesalers.

Wouter Verkerke is business developer for The Greenhouse Pharmacy at Wageningen Plant Research. His programme develops new growing strategies and new business models for new crops, aimed at the production of valuable food ingredients, cosmeceuticals and plant-based medicine. He is presently developing a new programme on Circular Horticulture, connecting stakeholders from industry with Wageningen R&D. Previously he founded the Bleiswijk Flavour Lab for fruits and vegetables, the clearing house that provides a level playing field for companies that are working towards higher flavour levels in fruits and vegetables, such as seed companies, growers, and wholesalers.

For more information: WUR Urban Greenhouse Challenge

WUR Urban Greenhouse Challenge

studentchallenges@wur.nl

urbangreenhousechallenge.nl